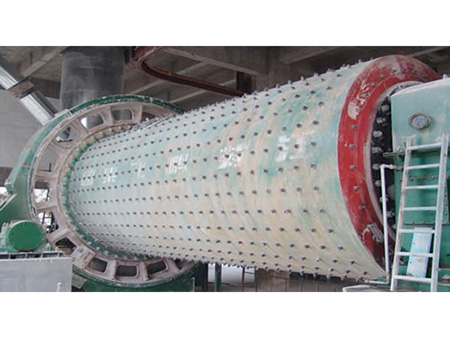

Raw Material Mill

Raw material mill is a key equipment for re-grinding materials which have already go through preliminary grinding in a crusher and been blended with other materials before. It is primarily applied for production of cement, silicate products, new type building materials, refractory materials, glass ceramic, etc.

Our mill comes into various specifications and models. They mainly adopt either edge-driving mode or center-driving mode. New style segregating liners and standard ladder liners are installed in the interior of the shell, which contributes to larger grinding superficial area and higher staging efficiency. In the newly designed diaphragm, there are adjustable and fixed lifting blades, which feature easy installation, maintenance and replacement.

Technical Parameters| Specification (m) | Woking Mode | Drive Mode | Reducer | Motor Power (kw) | Capacity (t/h) | Total Weight (t) | |

| Motor | Reduction Ratio | ||||||

| φ1.5×5.7 | Open Circuit | Edge-Driven | ZD40 | 3.55 | 130 | 4.5-6 | 25.8 |

| φ1.83×6.4 | Open Circuit | Edge-Driven | ZD60 | 4.5 | 210 | 7.5-15 | 43 |

| φ2.2×6.5 | Closed Circuit | Edge-Driven | ZD70 | 5 | 380 | 14-26 | 60 |

| φ2.4×7 | Closed Circuit | Edge-Driven | ZD70 | 5 | 475 | 24-28 | 81 |

| φ2.4×10 | Closed Circuit | Edge-Driven | ZD80-4- Ⅱ | 6.435 | 570 | 32-36 | 118 |

| φ2.6×10 | Closed Circuit | Edge-Driven | JDX710 | 6.3 | 800 | 45-50 | 130 |

| φ3×9 | Open Circuit | Edge-Driven | JDX800 | 6.3 | 1000 | 55-60 | 158 |

| φ3.2×9 | Closed Circuit | Edge-Driven | MBY900 | 7.1 | 1250 | 62-65 | 195 |

| φ3.5×10 | Open Circuit | Edge-Driven | JDX900 | 5.84 | 1250 | 70-75 | 200 |

| φ3.8×7.5 | Closed Circuit | Edge-Driven | JDX900 | 5.6 | 1600 | 80 | 233 |

| φ4.6×10 3.5 | Closed Circuit | Center-Driven | JQS3550 | 15.1 | 3550 | 190 | 415 |

| φ4.6×10.5 3.5 | Closed Circuit | Center-Driven | JQS3550 | 15.1 | 3550 | 210 | 476 |