Sulfur Recovery Catalyst

Request a Quote

Website: http://sino-catalysts.com

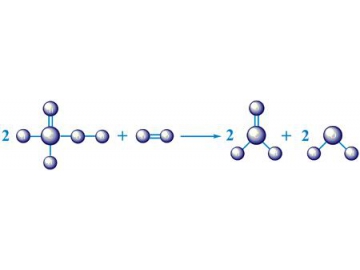

In the process of coal, petroleum and natural gas, a lot of H2S is produced. In order to protect environment and recover sulfur, Clause process is widely applied for processing acid gases containing H2S in industry.

According to many industrial applications of our sulfur recovery catalyst, the conversion rate of H2S generally is 65-75%. Second-stage Clause technology ensures a rate of 92-95% while three-stage Clause technology leads to a rate of more than 98%.

Technical Parameters of Sulfur Recovery Catalyst| Models | PSR-1 | PSR-21 | PSR-31 | PSR-41 | PSR-51 |

| Size (mm) | Φ 4-6, ball | Φ 4-6, ball | Φ 4 × 5-15, bar | Φ 4-6, ball | Φ 3 × 4-15, cloverleaf shape |

| Color | White | White | White | Red brown | Blue grey |

| Compositions (%) | AI2O3 ≥ 93Na2O3 ≤ 0.3 | AI2O3 ≥ 85TiO2 > 3 | TiO2 > 85 | AI2O3 ≥ 80FeO ≥ 6 | CoO > 2.5 MoO3 > 10 |

| Bulk density (g/ml) | 0.65-0.72 | 0.70-0.75 | 0.85-1.0 | 0.70-0.82 | 0.65-0.80 |

| Specific surface area (m2/g) | ≥ 300 | ≥ 260 | ≥ 100 | ≥ 260 | ≥ 200 |

| Porosity (m/g) | ≥ 0.4 | ≥ 0.35 | |||

| Crushing strength (N) | ≥ 150 | ≥ 130 | ≥ 100 | ≥ 150 | ≥ 130 |

| Catalyst attrition (%) | ≤ 0.5 | < 0.3 | ≤ 1.0 | ≤ 0.5 | ≤ 1.0 |

| Type | Universal type | Universal type | Anti-salinization type | Leakage protection type | Hydrogenation type |

You may also find products like:

Sulfur Removal Catalyst, Claus Catalyst, Sulfur Catalyst

Related Manufacturies

Leave Message

Manufacturer Advertising

More

Similar Manufacturies and Parts

Videos