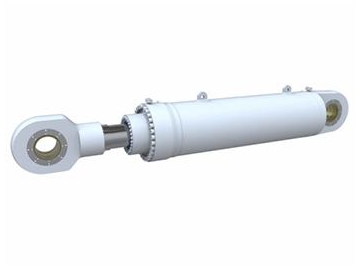

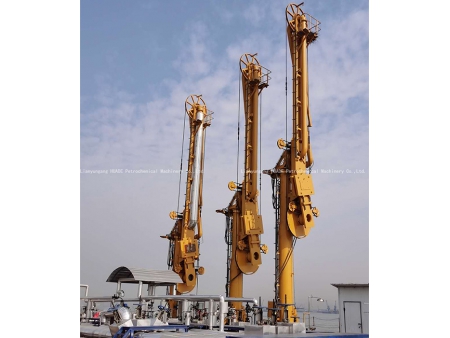

Hydraulic Cylinders for Marine and Port Equipment

Because the industrial world demands more powerful marine and port equipment requiring increased working pressure, Changjiang is responding with an expansive family of hydraulic cylinders for this purpose. By leveraging years of experience in the design, development and manufacturing of hydraulic cylinders, we are able to provide the right marine cylinder and port cylinder for your applications.

Features of Hydraulic Cylinder

Rated working pressure: 25MPa, unless otherwise specified

Construction: simple, high-strength

Working temperature: -20~ 80°C, unless otherwise specified

Sealing system

Due to high corrosion involved in the marine environment, hydraulic cylinder of this series comes in a unique protective design to avoid damage. Sealing elements come from PARKER and MERKEL, preventing seawater ingress and leak of hydraulic fluids. These seals also protect lubricating oil film around the piston rod, thereby extending their use life.

Piston Rod

Precision-honed piston rod is made of either stainless steel or low-alloy steel. Reinforced rod design has undergone heat treatment. Chrome over nickel rod plating for additional corrosion resistance is polished via a CNC system. Below are short descriptions outlining several commonly used piston rods.

1. Chrome over nickel plating

2. Rod end with welded stainless steel ferrule

3. Stainless steel piston rod

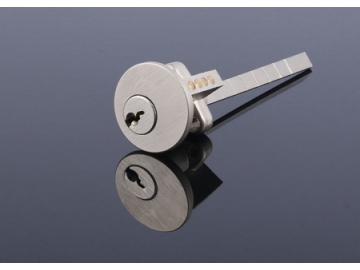

Cylinder Gland

The length of the part of the gland that provides support is in proportion to that of the part that offers guide. Made of phenolic resin, the guide ring offers high load capacity and avoids the metal-to-metal contact between the piston rod and the cylinder gland. Because of the many seals housed inside the cylinder gland, an improved service life, shock absorption capability, and side load capacity can be achieved.

Cylinder

Constructed form high-strength low-carbon alloy steel, the hydraulic cylinder has been through cold extrusion, skiving and roller burnishing processes to obtain an attractive surface finish and excellent hardness. A smooth surface means less friction and does wear down easily over time. It also means improved service life of the sealing elements. This cylinder is ideal for use at low temperatures.

Piston, Piston Seals

Threaded piston is a one-piece design and mates with the threads on the piston rod. Piston seals are either model ZW from PARKER or L43 from MERKEL which is suitable for use on double-acting cylinders. In tight spaces where movement is limited, the piston seal not only guides the rod, but it also seals any gap between the piston and the cylinder. Made of nitrile rubber, these piston seals provide maximum sealing performance and can retain their original irregular shapes during installation without kinks.

Welding

Using robotic arms to perform welding eliminates inconsistency in weld quality which is inevitable if done manually. Specialized personnel are responsible for detecting weld defects if there is any using ultrasonic flaw detector.

Surface Treatment

Unless otherwise specified, all marine cylinders and port cylinders are sandblasted to Sa 2.5 in strict compliance with ISO6501 standards. To fight against corrosion, we offer two measures for choice.

1. Inorganic zinc rich ethyl silicate based primer: 60um to 120um thick

2. Epoxy zinc-rich primer: 50um; Polyurethane: 150um

Testing

Upon shipping out your order, all hydraulic cylinders need to be put through rigorous tests at pressure 1.5 times their rated working pressure which last for 5 minutes. During the test, the cylinder is required to complete the 2-stroke cycle, partly extend, and start running at a certain pressure. Hydraulic fluids used in the test should meet NAS6 requirements and must contain substances that prevent sulphide pollution.

Delivery: Cleaning, storage

Delivery: Delivered goods are consistent with the purchase order

Cleaning: Hydraulic fluids inside the cylinder should meet NAS7 standards.

Storage: All ports are plugged with steel plugs. Grease is applied to the surface of the piston rod for corrosion resistance.

Safety Features (Optional)

We offer stroke counter, shut-off valve, and features that enable a slow return stroke.