Magnetic Deburring Machine

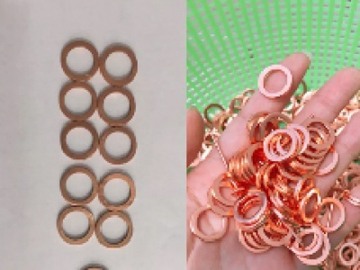

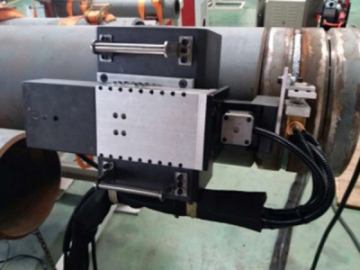

The magnetic deburring and polishing machine performs batch deburring and polishing on metal components and precision parts used in automotive, aerospace and electronics industries. This magnetic deburring machine is ideal for removing burrs and achieving smooth finish for large, cylindrical or complex parts with external & internal threads, slots or holes, where precision is critical and manual polishing method can not reach.

This magnetic deburring machine suitable for deburring and finishing of metals including aluminum, copper, stainless steel, gold, silver, zinc, magnesium, iron, and rigid plastic parts.

- Semi-permanent magnet stainless steel pins are used as magnetic media, low material consumption and low cost;

- Quick deburring of 5-15 minutes per cycle time, rapid tool change without interruption of the machine;

- Variable frequency adjustment can meet various processing needs;

- Capable of polishing irregular parts, including dead angles;

- Easy and safe to operate, multiple machines can be controlled by one person;

- Voltage, current, frequency and time can be simply and easily controlled;

- Parts can be completely polished without deformation, dead angles and surface damage, as well as any effect on precision;

Power supply: AC380V(50/60HZ)

Motor power: 2.2kW (2 pieces)

Machine size (L×W×H): 1650mm×620mm×725mm

Control panel size (L×W×H): 530mm×350mm×1050mm

Tank size (L×W×H): 1550×520mm

Max. processing capacity: 28-32kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 425kg

Stainless steel pin: 6kg

Deburring solution: 50L

Deburring tank: 1pc

Rubber pad: 1pc

Separating screen: 1pc

Power supply: AC220V (50/60HZ)

Motor power: 2.2kW

Machine size (L×W×H): 1180mm×620mm×680mm

Control panel size (L×W×H): 530mm×350mm×1050mm

Tank size (L×W×H): 1080×520mm

Max. processing capacity: 16kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 266kg

Stainless steel pin: 4kg

Deburring solution: 50L

Deburring tank: 1pc

Rubber pad: 1pc

Separating screen: 1pc

Power supply: AC380V (50/60HZ)

Motor power: 5.5kW (2 pieces)

Machine size (L×W×H): 2060mm×730mm×755mm

Control panel size (L×W×H): 530mm×350mm×1050mm

Tank size (L×W×H): 1960×630mm

Max. processing capacity: 32-36kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 458kg

Stainless steel pin: 6kg

Deburring solution: 50L

Deburring tank: 1pc

Rubber pad: 1pc

Separating screen: 1pc

Power supply: AC380V(50/60HZ)

Motor power: 4kW

Machine size (L×W×H): 1000mm×730mm×755mm

Control panel size (L×W×H): 530mm×350mm×1050mm

Tank size (L×W×H): 900×630mm

Max. processing capacity: 18-22kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 288kg

Stainless steel pin: 4kg

Deburring solution: 50L

Deburring tank: 1pc

Rubber pad: 1pc

Separating screen: 1pc

Power supply: AC380V(50/60HZ)

Motor power: 4kW

Machine size (L×W×H): 1000mm×810mm×1180mm

Tank size (L×W×H): 730×630mm

Max. processing capacity: 15-18kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation, no dead angle

Machine weight: 235kg

Stainless steel pin: 4kg

Deburring solution: 50L

Deburring tank: 1pc

Rubber pad: 1pc

Separating screen: 1pc

Power supply: AC380V(50/60HZ)

Motor power: 4kW

Machine size (L×W×H): 950mm×810mm×1080mm

Tank size (L×W×H): 680×630mm

Max. processing capacity: 13-15kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 196kg

Stainless steel pin: 4kg

Deburring solution: 50L

Deburring tank: 1pc

Rubber pad: 1pc

Separating screen: 1pc

Power supply: AC380V(50/60HZ)

Motor power: 5.5kW (3 pieces)

Machine size (L×W×H): 2060mm×730mm×755mm

Control panel size (L×W×H): 530mm×350mm×1050mm

Tank size (L×W×H): 1960×630mm

Max. processing capacity: 50kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 555kg

Stainless steel pin: 6kg

Deburring solution: 50L

Deburring tank: 3pcs

Rubber pad: 1pc

Separating screen: 1pc

Power supply: AC380V(50/60HZ)

Motor power: 5.5KW (2 pieces)

Machine size (L×W×H): 1300mm×730mm×775mm

Control panel size (L×W×H): 530mm×350mm×1050mm

Tank size (L×W×H): 1200×630mm

Max. processing capacity: 30-36kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 350kg

Stainless steel pin: 4kg

Deburring solution: 50L

Deburring tank: 2pcs

Rubber pad: 1pc

Separating screen: 1pc

User manual: 1pc

Power supply: AC220V(50/60HZ)

Motor power: 1.5kW

Machine size (L×W×H): 640mm×600mm×1080mm

Tank size (L×W×H): 420×420mm

Max. processing capacity: 8-10kg

Processing speed: 0-60Hz

Rotation: forward/reverse rotation

Machine weight: 130kg

Stainless steel pin: 2kg

Deburring solution: 20L

Deburring tank: 1pc

Rubber pad: 1pc

Separating screen: 1pc

User manual: 1pc