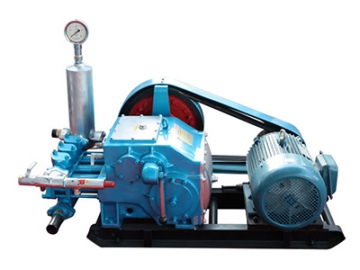

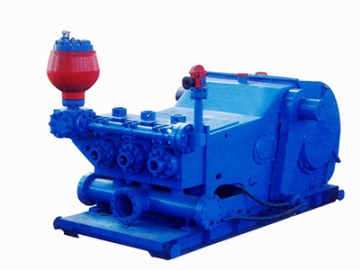

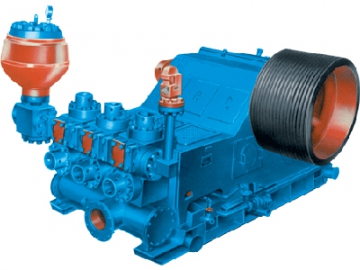

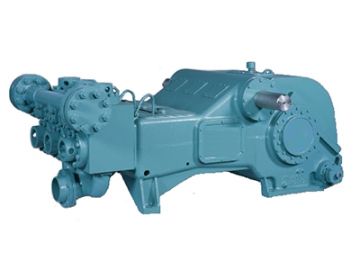

Mud Pump

Plunger Pump/ Reciprocating Pump/ Piston Pump

This series of mud pumps are applied in oilfields and other industrial mining operations all over the world. All of our mud pumps are manufactured in strict accordance to API spec 7k and are thoroughly tested for a quality guarantee. These plunger pumps are designed to handle all sorts of drilling requirements, such as high pump pressure and large displacement conditions that would be found in oil field applications.

The piston pump has a longer stroke compared to similar designs and can operate at a lower stroke if need be to improve the water supply performance. The forced lubrication of the power end of the pump promotes incredible efficiency and allows for a longer working lifetime.

Cost-Effective:

We always insist that quality comes first, and for that reason, you can be sure that all of our equipment is produced using the highest quality materials that will perform up to your expectations. Maximum cost effectiveness is achieved, particularly when taking in consideration the longevity of our reciprocating pumps.

Advantages:

1. The mud pump plays an important role in mud circulation system. According to the driving method, mud pumps can be driven using a diesel engine, natural gas engine and electric motor. It can transport 35Mpa (5000PSI) high pressure liquid with a large displacement. The pressure depends on the piston size and rated power of the pump. Power range: 350HP-2200HP.

2. Designed and manufactured in accordance with API 7K, ISO9001 standards.

3. Forged alloy steel bull/pinion gears for smooth matching, quiet running, and extended service life which is unique in the mud pump industry

4. Balanced forged alloy steel crankshaft.

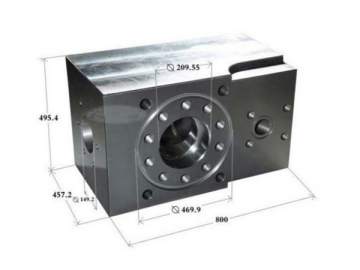

5 Alloy steel plate welded frame with CNC machining to ensure assembly accuracy.

6. Self-aligning packing to prevent leaks and extend service life.

7. Interchangeable components and parts with major mud pumps to facilitate repair and maintenance.

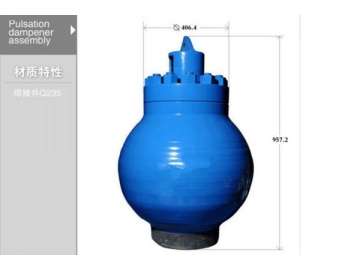

8. Optional 10G 3K or 20G 5K pulsation dampener, forged alloy steel 6-way strainer block.

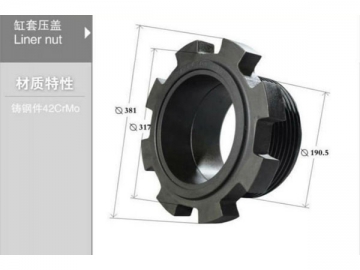

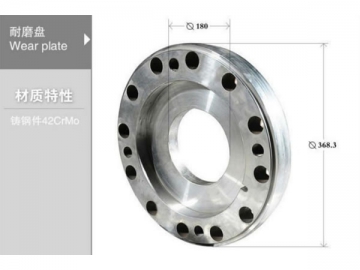

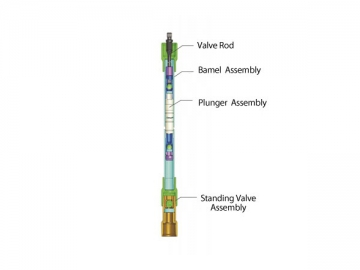

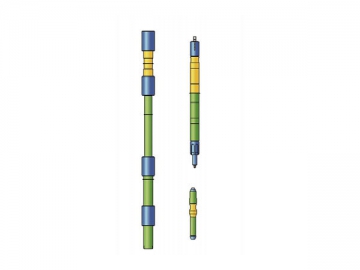

Spare and Accessory Parts:

Testing & Commissioning:

1. Install and secure major machinery and miscellaneous equipment

2. Furnish lube products for testing

3. Run diesel engine to test transmission devices.

Documentation:

1. Operating & Maintenance Manuals (1 set)

2. Product Certificate (1 set)

3. Part list Manual of mud pump (1 set)

F1000 Mud Pump packed and ready to be shipped to Wellman, Kazakhstan.

Technical Parameters:

| Model | F-500 | F-800 | F-1000 | F-1300 | F-1600 |

| Bore * Stroke (in) | 6 3/4 * 7 1/2 | 6 3/4 * 9.0 | 6 3/4 * 10 | 7 * 12 | 7 * 12 |

| Speed Rated (SPM) | 165 | 150 | 140 | 120 | 120 |

| Horse Power rated (HP) | 500 | 800 | 1000 | 1300 | 1600 |

| Gear Type | Herringbone | ||||

| Gear Ratio | 4.286:1 | 4.185:1 | 4.207:1 | 4.206:1 | 4.206:1 |

| Lubricating | Pressure & splash | ||||

| Suction Inlet | 8" Flange | 10" Flange | 12" Flange | 12" Flange | 12" Flange |

| Discharge outlet | 4" Flange * 5M | 5" Flange * 5000 PSI API | |||

| Pinion Shaft (in) | 5 1/2 | 7 | 7 3/4 | 8 1/2 | 8 1/2 |

| Keys (in) | 1 1/4 * 1 1/4 | 1 3/4 * 1 3/4 | 2 * 2 | 2 * 2 | 2 * 2 |

| Valve pots | API 5# | API 6# | API 6# | API 7# | API 7# |

| Valve Cover | Screw type | ||||

| Cylinder Head | Screw Type | ||||

| Liner Lock | Screw type, metal-metal | ||||

| Weight (kg) | 9,770 | 14,500 | 18,790 | 24,572 | 24,791 |