Plastic Recycling Systems (Washing / Drying / Separating)

Whether you need to recycle waste plastic film, pipe, bottles, or agricultural waste, HS Machine offers an extensive range of custom plastic recycling systems to meet each of your needs.

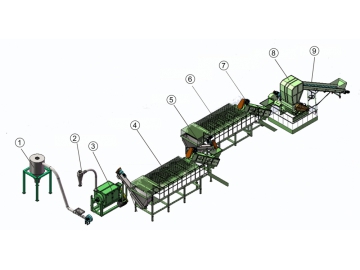

- Silo

- Cyclone Separator

- Extrusion Dryer

- Sink Float Tank

- Screw Extrusion Conveyor

- Sink Float Tank

- Plastic Washing System

- Shredder

- Belt Conveyor

Haosu will design and manufacture a complete plastic recycling system, including washing, drying, and separating for a highly effective recycling process of used and contaminated plastic waste.

Processes for contaminated plastics include the removal of packaging materials such as foils and pallets/packaging straps. Any residues left behind such as paper labels or liquids inside the PET bottles are considered impurities and are removed via washing equipment.

Metal detectors are designed to detect and separate metal contaminants. They control the material flow in the metal search bridges on the product conveyor, stopping the conveyor when metal contaminants are detected. These contaminants are then removed in the float-sink process.

It is easy to carry out mechanical separation of coarse foreign materials using a vibrating screen or screen drum. Depending on further processing needs for the produced plastic flakes, they will be sent to residual moisture equipment so that they are fed to an extruder. These plastic flakes are then pre-dried using a mechanical centrifugal dryer. If needed, they will also be sent to the final drying process inside thermal dryers.