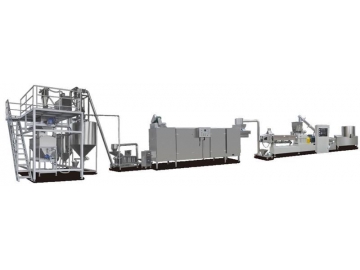

Mixed Grain Manufacturing Production Line

Introduction

Mixed grain manufacturing production line has effectively improved disadvantages of original process and characterized by high degree of automation, strong stability, simple operation, high yield, short process time, etc. It is a new and efficient nutrition powder production line and it can be used to product various products like baby rice powder, sesame paste, walnut paste, etc.

- The mixed grain manufacturing production line is highly automated and requires only two people to operate.

- It is controlled by PLC and easy to operate.

- Its throughput is 100-1000kg/h.

- It is controlled by frequency controller. So it is energy saving.

- It is flexible and free from site restrictions.

Production process

Raw material mixture – puffing – drying – pulverizing - recombination - packaging

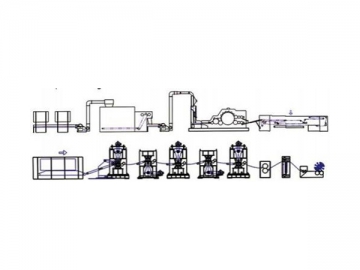

Equipment flowsheet

Flour mixer → Food process extruder with twin screw → Blower → Three-layer electric oven → Pulverizer → Mixer

| Model | Installed Power | Actual Consumption | Throughput | Dimension | |

| SX65-III | 75KW | 50KW | 120-150Kg/h | 24x1.2x2.0m | |

| SX85-II | 130KW | 80KW | 300-400Kg/h | 28x1.5x2.0m |

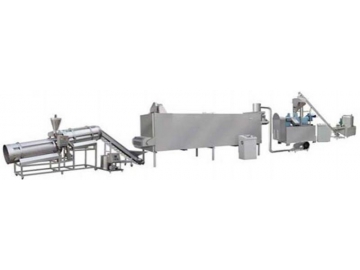

Food process extruder with twin screw

Introduction

The food process extruder with twin screw of Luerya is consisted of feeding system, extrusion system, rotary-cut system, heating system, drive system, cooling system and control system.

- Frequency control has strong power and can turn round stably, it is used in feeding system, driving system and rotary-cut system.

- To ensure safe operation of the extruder, it was designed with self-lubrication and forced cooling.

| Model | Installed Power | Actual Consumption | Main Motor Consumption | Throughput | Dimension | |

| SX65-IIIA | 35KW | 28KW | 22KW | 120-150Kg/h | 2.5x1.0x1.6m | |

| SX65-IIIB | 60KW | 40KW | 22KW | 150-200kg/h | 3.5x1.0x1.8m | |

| SX85-II | 120KW | 60KW | 90KW | 300-500kg/h | 4.0x1.2x3.0m | |

| SX65-I | 70KW | 40KW | 30KW | 100-150kg/h | 3.5x1.0x1.8m |

SXK5-D three-layer oven (electric type)

Introduction

The oven can be applied in many fields. It can be used to dry all kinds of bars, lumps, granule and other extruded food or other materials. Users can choose toast ovens with different layers, different lengths and different heat source according to the materials.

- It is designed with round-trip drying. Double pitch roller chain drive is used in all drive system of the machine, so it can operate smoothly and stably.

- The toast oven is designed with high efficient energy-saving combustion system which can distribute heat source reasonably.

- So the materials can be heated uniformly and the oven has low energy consumption and high throughput.

| Model | Power/Oil Consumption | Heating Temperature | Throughput | Dimension | |

| SXK3-D three-layer oven | 27.5KW/h | 220℃ | 180-300kg/h | 5.0x1.2x1.7m | |

| SXK3-Y three-layer oven | 7L/h | 220℃ | 180-300kg/h | 5.0x1.5x2.0m | |

| SXK3-YI three-layer oven | 8L/h | 220℃ | 400-600kg/h | 8.2x1.6x1.8m |

Index

food processing equipment, commercial food machines, food manufacturing line, puffed food machines