Fire Resistant Sleeving

Description

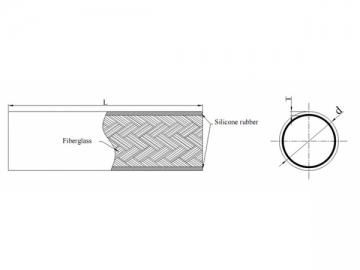

Our fire-proof sleeving is fabricated using a special dense E-class fiberglass with a thick coating of self-extinguishing, high temperature silicone rubber. This silicone rubber is engineered to protect hoses, cables and wire harnesses from damage due to exposure to extreme heat, open flame and molten splashes.

The fire resistant sleeving also provides a high degree of insulation value, protects hot and cold cryogenic lines, pipes and tubing from heat or cold loss, which saves energy and the tubing itself is abrasion resistant.

Application

Fire-proof sleeving is used to protect fuel lines, hydraulic and oil lines from heat and to prolong the service life of wiring and hoses in the event of a fire, to allow critical systems to function longer, such as in the aviation and marine fields.

Technical data

Material: Fiberglass fiber silicone

Working temperature range: -50℃~ 500℃

Instantaneous temperature: 1150℃

Flammability: Self-extinguishing-VW-1

Color: Brick red

Approval: RoHS

Voltage: 7.0KV

Cutting tool: Scissors

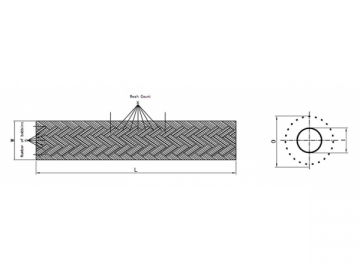

Drawing

DrawingUnit: mm

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-008 | 8±1 | 12±1 | 2 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-010 | 10±1 | 14±1 | 2.2 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-012 | 12±1 | 16±1 | 2.2 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-015 | 15±2 | 19±2 | 2.2 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-020 | 20±2 | 25±2 | 2.5 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-025 | 25±2 | 31±2 | 2.8 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-030 | 30±2 | 36±2 | 3 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-035 | 35±2 | 41±2 | 3.2 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-040 | 40±2 | 47±2 | 3.5 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-045 | 45±2 | 53±2 | 3.8 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-050 | 50±3 | 59±3 | 4 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-055 | 55±3 | 64±3 | 4.2 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-060 | 60±3 | 70±3 | 4.5 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-065 | 65±3 | 75±3 | 4.5 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-070 | 70±3 | 80±3 | 4.8 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-075 | 75±3 | 85±3 | 4.8 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-080 | 80±3 | 90±3 | 5 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-085 | 85±3 | 96±3 | 5.3 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-090 | 90±3 | 101±3 | 5.6 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-095 | 95±3 | 106±3 | 5.8 |

| Part No. | I.D. ( d ) | O.D. ( D ) | Wall thickness |

| MGWG-100 | 100±3 | 112±3 | 6 |