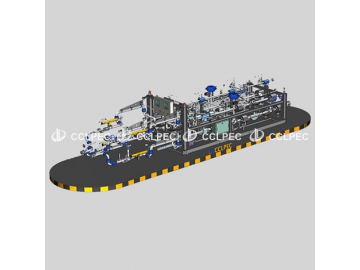

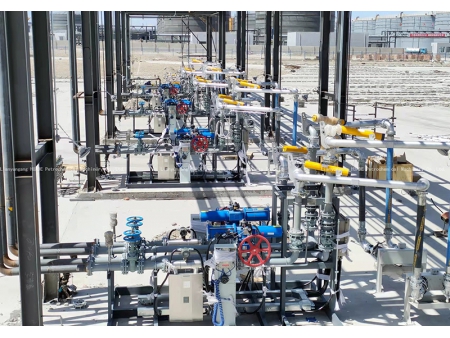

LNG Loading Skid

CCLPEC has accomplished LNG loading skid projects for over 17 LNG terminals in local market, and 4 LNG terminals in foreign markets. CCLPEC’s LNG loading system has a market share over 85% in local market. The LNG loading skid is capable of transferring LNG to tank trucks, which is featured by high integration. Due to the cryogenic property of the medium, LNG loading skid is configured with specially designed pipeline, instruments, valves and control system.

Features

- This metering and loading skid is manufactured in accordance with the requirements of EPC and international standards and specifications, particularly can meet the requirements of customer’s project. The safety design meets the requirements of SIS and HAZOP while the electrical system satisfies explosion protection requirements of ATEX and IEC.

- Main pipelines generally include liquid pipeline, vapor pipeline, cold circulation pipeline, venting pipeline, nitrogen purging pipeline and instrument air pipeline, ensuring that the loading operation is safe, quick, easy to control and accurate in loading capacity.

- LNG loading skid can be equipped with LNG loading arm or LNG hose to connect the LNG tank truck.

- Batch controller is specially designed for LNG loading operation, which integrates display screen, IC card reader and keyboard. Coupled with automatic control valves in each pipeline, the batch controller is able to automatically control the loading processes: leakage detection → nitrogen purging → pre-cooling → small volume loading → mass loading → purging, thus accomplishing loading operation with one key. Operator will be guided to perform standardized operation to reduce incorrect operation and improve operator’s safety.

- Static grounding control unit is interlocked with batch controller, it can be equipped to real-time monitor the earthing status of road tanker or railcar.

- Thanks to the modular design, the metering and loading skid can be easily put into use by connecting pipeline flanges and cables. The assembling and commissioning are completed in our workshop, greatly saving time of on-site installation.

- Shut-off valves in liquid and vapor pipelines are directly connected to safety instrumented system (SIS) in the plant, or configured with dual solenoid valves to realize double control. The main valves on pipelines can be controlled utilizing pneumatic actuator according to customer’s request, enhancing automatic control level for the loading skid.

Related products

Send Message

Most Recent

More

Other Products

Videos