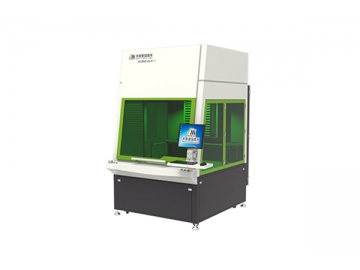

350W Light Guide Plate Laser Dotting Machine, MC350-DLG-D Laser System

Applicable Materials

The MC350-DLG-D laser system is applicable for acrylic/light guide plate non-metallic materials, such as LCD, LED flat lamp, indicator, X-ray light box and so on.

| Model | Laser power (W) | Working area (mm) | Minimum line width (mm) | Minimum character (mm) | Speed (m/min) | Overall dimension (mm) | Weight (Kg) | Supply voltage | Working environment | Gross powe (kW) |

| MC350-DLG-D | 350 | 1200×1200 | Up to format size | 3 | 0~15000 | 1700 × 2670 × 2430 | ≤1200 | AC220V±10%, AC380V±10%, 50Hz/60Hz | Temp: 10~35°C, Humidity:5~85%. No condensate water, no dust or less dust. | ≤12.5 |

Laser Processing Examples:

- Laser dotting on acrylic

- Laser dotting on ad light guide box

- Laser dotting on ad light guide plate

- Laser dotting on flat light

- Laser dotting on light guide plate

- Laser dotting on luminescent screen

- Laser dotting on panel light

- Laser dotting special light guide plate

Product Feature

1. The CO2 laser generator imported with original packaging has advantages of high-quality light spot, laser power with uniform density and stable output laser power.

2. Imported automatic focusing triaxial dynamic scanning system has advantages of impact structure, sturdy and stable, good dust-proof effect, easy and quick assembly, strong anti-jamming capability, which ensures the system high-speed and stable operation under long-term working conditions.

3. The Beam expander and reflector of external light-path transmission system are both imported, which have good shaping effects, high transmittance and reflectance, extremely small luminous decay and high stability. Thus it ensures uniformity of node distribution.

4. The vac-sorb platform is equipped with high-pressure vortex pump, which ensures that acrylic materials are smoothly absorbed into platform. Thus it can effectively avoid potential risks brought by coarse surface of raw materials.

5. An enclosed type design helps prevent users from being affected by laser radiation and effectively remove dust to achieve safety and environmental protection.

6. Independently researched and developed professional light guide plate software can do graphic net-point design of light guide plate with any size or any shape. It has advantages of easy operation and fast data processing speed. It is also compatible with GTools light guide plate design software, which has fast processing speed, high working efficiency and strong illumination intensity.

7. No need for splice. It can manufacture light guide plate with different format at one sequence, including 300*300mm, 300*600mm, 600*600mm, 600*1200mm, 1200*1200mm.