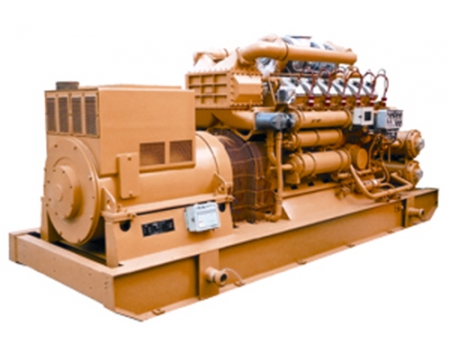

Coal-bed Methane Generator (600kW/1100kW)

Coal mine methane is also a kind of high-quality energy with high thermal efficiency and less pollution. Coal mine gas is used for power generation, and waste heat recovery equipment is used for recovering the heat of engine exhaust. It can not only reduce greenhouse gas emissions, help develop a recycling economy but also can ease the contradiction between supply and demand of electricity.

Biogas is used for power generation, and waste heat recovery equipment is used for recovering the heat of engine exhaust. Therefore it can realize cogeneration, develop a recycling economy, and the comprehensive utilization efficiency of biogas can reach over 70%. It can not only reduce environmental pollution, benefit the environment, reduce greenhouse gas emissions, but also can ease the contradiction between supply and demand of electricity, reduce production costs, increase the efficiency of enterprises, and increase the competitiveness of enterprises.

Since 2002, CNPC JICHAI has always been devoted to the R&D of biogas engines. After years of efforts, coal-bed methane generator (600kW/1100kW) has been developed which can also be assembled as generator sets to fit different applications.

Since 2005, we have increased investment in R&D of coal mine gas power generation products, focusing on communication and cooperation with relevant scientific research institutes in coal mines, and coal bed methane in China. Advanced control technology and lean combustion technology is adopted to ensure that the gas concentration fluctuates greatly. Through the reasonable matching of the inlet system, the gas turbine unit with gas pressure of 3-15KPa can burn 8%-60% of the methane concentration. Its high safety level and long-lasting reliability guarantee a long service life. Our economical, safe and reliable products have reached the international advanced level.

- Rated power: 1512W, 6016W

- EGS-02 gas electronic control for the closed-loop control in the running process

- Advanced air-fuel ratio control technology: TEJCT system

- High-flow and high-pressure air inlet system adapts to wide variations in concentration (30% to 60% methane concentration)

- IG-NT synchronizing controllers and automatic load balancing

- 2500 hours of trouble free operation

- Electronic monitoring technology to supplement supervision of generator parameters

- Distributed energy systems with heating, cooling and electricity generated at the point of use

- Voltage class: 0.4KV, 6.3KV, 10.5KV

| Genset model | 600GF-W | 1100GF-W | |

| Alternator model | 1FC series, Siemens technology, brushless excitation, automatic voltage control | ||

| Control panel | GPL600 | GPL1000 | |

| Rated power (kW) | 600 | 1100 | |

| Rated voltage (V) | 400V/6300V/10500 | ||

| Rated frequency (Hz) | 50 | ||

| Rated power factor | 0.8 | ||

| Wiring method | Three-phase four-wire, star connection | ||

| Protection class | IP23 | ||

| Insulation class | H | ||

| Stabilized voltage adjusting rate | ≤±2.5% | ||

| Instantaneous voltage adjusting rate | ≤ 20%(-15) | ||

| Voltage recovery time | ≤1.5 s | ||

| Fluctuation of voltage | ≤1.0% | ||

| Stabilized frequency adjusting rate | 0~5% | ||

| Instantaneous frequency adjusting rate | ≤±10% | ||

| Frequency recovery time | ≤7 s | ||

| Fluctuation of frequency | ≤0.5% | ||

| Overall dimension (mm) | 5120×2040×2776 | 6198×2540×2180 | |

| Weight (kg) | 13800 | 21000 | |

| Engine model | G12V190ZLTW-2 | H16V190ZLTW-2 | |

| Type | Four-stroke, V-shaped, turbocharged, inlet air cooling, spark ignition,external-mixing electronic control | ||

| Number of cylinder | 12 | 16 | |

| Bore (mm) | 190 | 190 | |

| Stroke (mm) | 210 | 215 | |

| Total displacement (L) | 71.5 | 97.53 | |

| Rated speed (r/min) | 1000 | 1000 | |

| Rated power (kw) | 650 | 1100 | |

| Idle speed | 700r/min | ||

| Gas pressure | 100~400 KPa | ||

| Gas consumption | ≤11000kJ/kW·h | ≤9500kJ/kW·h | |

| Oil consumption | ≤0.8g/kW·h | ≤0.6g/kW·h | |

| Exhaust temperature (before turbine) | ≤650℃ | ||

| Warm water temperature | < 85℃ | ||

| Intercooler water temperature | < 45℃ | ||

| Oil temperature | < 90℃ | ||

| Speed regulation rate | 0~5 % | ||

| Type of cooling | Water cooling, open type with cooling tower, close type with vertical radiator or horizontal radiator | ||

| Lubrication method | Press and spray lubrication | ||

| Starting method | Electric starting | ||

| Direction of rotation | Anticlockwise (facing the power output end) | ||

- The coal mine gas genset power plant project in Shanxi

- The coal mine gas genset power plant project in Shanxi

- The coal mine gas genset power plant project in Ningxia

CNPC JICHAI was formed in 1920, we are a prestigious brand in China and is a global leader in internal conbustion engine and generator set manufacturing. Our power solutions are designed to improve your performance and productivity.