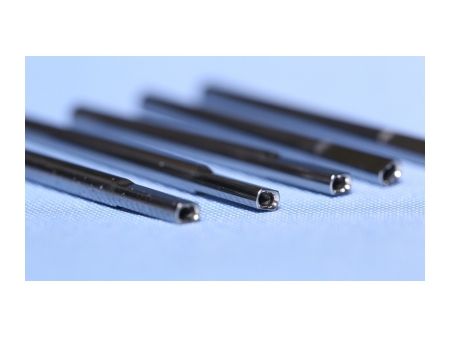

Tungsten Carbide Nozzle

Description

The tungsten carbide nozzle is used primarily on the fully automatic winding machine for high speed winding of fine coils, and ultra-thin enameled wire grinding. It is often used for electronic appliance production processes, such as that for transformers, inductors, and voice coils.

Features

(1) The tip of this nozzle is finely machined using ultra-fine tungsten carbide particles with a hardness of HRC90. The bending resistant performance is 2300N/mm.

(2) Qianhe uses specific equipment for fine grinding processing and inner hole fine grinding and cutting processing so that the roughness of the inner hole is Ra 0.1, while the roughness of the R parts at two ends is Ra 0.025.

(3) The scientific design of the curvature radius of the wire inlet and outlet at two ends ensures a smooth and natural wire passing. There is no zigzagging inside the nozzle, which prevents easy bending and blocking.

Parameter| Specification | Total length L | Minor diameter L1 | Major diameter D | Minor diameter D1 | Hole diameter of the wire outlet d1 | Hole diameter of the wire inlet d2 | |

| W0202-2005-1505 | 15 | 5 | 2 | 0.5 | 0.2 | 0.2 | |

| W0202-2000-3300 | 33 | * | 2 | * | 0.2 | 0.2 | |

| W0202-3010-3015 | 30 | 15 | 3 | 1 | 0.2 | 0.2 | |

| W0202-3006-3010 | 30 | 10 | 3 | 0.6 | 0.2 | 0.2 | |

| W0202-3015-3015 | 30 | 15 | 3 | 1.5 | 0.2 | 0.2 | |

| W0202-3007-3508 | 35 | 8 | 3 | 0.7 | 0.2 | 0.2 | |

| W0303-3008-3012P | 30 | 12 | 3 | 0.8 | 0.3 | 0.3 | |

| W0303-3012-3519 | 35 | 19 | 3 | 1.2 | 0.3 | 0.3 | |

| W0303-3008-4506 | 46 | 6 | 3 | 0.8 | 0.3 | 0.3 | |

| W0303-3020-3515 | 35 | 15 | 3 | 2 | 0.3 | 0.3 | |

| W0303-0800-3500 | 35 | * | 0.8 | * | 0.3 | 0.3 | |

| W0303-3018-4018 | 40 | 18 | 3 | 1.8 | 0.3 | 0.3 | |

| W0404-3010-3009 | 30 | 9 | 3 | 1 | 0.4 | 0.4 | |

| W0404-3007-4528 | 45 | 28 | 3 | 0.7 | 0.4 | 0.4 | |

| W0505-3012-4506T | 45 | 6 | 3 | 1.2 | 0.5 | 0.5 | |

| W0606-3012-3520 | 35 | 20 | 3 | 1.2 | 0.6 | 0.6 | |

| W0606-3016-4010T | 40 | 10 | 3 | 1.6 | 0.6 | 0.6 | |

| W0808-3018-3518 | 35 | 18 | 3 | 1.8 | 0.8 | 0.8 | |

| W0808-3018-3010 | 30 | 10 | 3 | 1.8 | 0.8 | 0.8 | |

| W1212-3022-3010 | 30 | 10 | 3 | 2.2 | 1.2 | 1.2 |

Note: the listed are standard specifications. Non-standard products can be customized according to customer requirements.