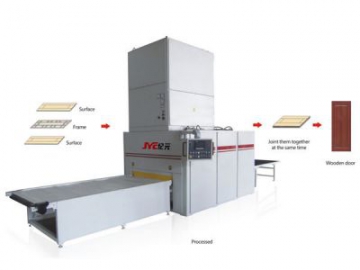

Radio Frequency Press Curved Plywood Press

The curved plywood press is also known by two other names: a radio frequency press, or hot press. It is another one type of Jiyuan's specially designed woodworking machinery. The plywood machinery utilizes a hydraulic system, allowing pressure to come in from a single direction or three different directions, and is suitable for bending wood in a variety of different angles.

For plywood that has basic dimensions, the heating process for curving the plywood takes only 1 to 3 minutes, a process that is both faster and better in comparison to the traditional steam heating method. It is especially useful for thicker wood, showing its superiority with its radio frequency heating. This radio frequency press is widely used for furniture manufacturing, musical instrument production, shoe material processing, and craft making.

As one of our most popular selection of radio frequency press, our curved plywood press can be used to bend different types of plywood, MDF and HDF boards. It is an excellent solution for processing manufacturing curved wood for office furniture, children's furniture, chairs, tea tables, sofa armrests, bed slats, paneled furniture, bed headboards, cabinet door faces and musical instruments such as guitars.

Our curved plywood press was one of our early radio frequency presses that we designed, and is now exported to more than 30 countries around the world.

Characteristics of the Curved Plywood Press

1. The use of high frequency dielectric heating ensures a uniform heating and glue cures quickly in as little as 3 minutes.

2. A wooden mold can easily be made, while still maintaining a low cost, making the radio frequency press great for users who often change the bending shape.

3. This plywood machinery does not need to use a boiler, which means that no smoke or dust are emitted, making it environmentally friendly.

4. Its superiority with the use of radio frequency heating is more apparent the thicker the wood is.

5. Two radio frequency presses share one RF generator. When one press is working, the other can be used to prepare materials, reducing work time and improving efficiency.

6. The finished product features a stable shape that is difficult to deform.

7. The RF press can be customized according to plywood shape and size that needs to be bent.

8. Best-in-class accessories ensure a stable operation.

9. Its user-friendly design makes operation easier.

Applications and Technical Parameters of the Curved Plywood Press

| Model | ||||

| Main voltage | 3 phase, 380V, 50Hz or customized | |||

| Output power | 20KW | 20KW | 20KW | 20KW |

| Working table size | 1200×600mm | 1500×800mm | 1200×600mm | 1500×800mm |

| All working table sizes can be customized | ||||

| Pressure | 60T | 80T | 120T | 160T |

| Output type | Two sets of RF press share one RF generator (shift to work) | |||

| Model | ||

| Main voltage | 3 phase 380V, 50Hz or customized | |

| Output power | 20KW | 30KW |

| Working table size | 1600×800mm | 2000×1000mm |

| All working table sizes can be customized | ||

| Pressure | 100T | 120T |

| Output type | Two sets of radio frequency press share one RF generator (shift to work) | |

| Model | ||||

| Main voltage | 3 phase 380V, 50Hz or customized | |||

| Output power | 20KW | 30KW | 20KW | 30KW |

| Working table size | 1600×800mm | 2000×1000mm | 1600×800mm | 2000×1000mm |

| All working table sizes can be customized | ||||

| Pressure | 100 T | 120T | 160T | 160T |

| Output type | Two sets of RF press share one RF generator (shift to work) | |||

| Model | |||

| Main voltage | 3 phase 380V, 50Hz or customized | ||

| Output power | 20KW-30KW | ||

| Working table size | 1600×800mm | 1500×700mm | 1600×800mm |

| All working table sizes can be customized | |||

| Vertical pressure | 100T | 80T | 100 |

| Horizontal pressure | 8T ×2 | 30T × 2 | 30T × 2 |

| Total pressure | 116T | 140T | 160T |

| Output type | Two sets of RF press share one RF generator (shift to work) | ||

| Model | |

| Power supply | AC 380V, 50Hz, 3 phases, 4 wires or customized |

| Output power | 15KW |

| Heating time | 10-20 seconds |

| Frequency | 6.78Mhz |

| Output type | Two sets of radio frequency press share one RF generator (shift to work) |

| Total weight | 1.5T |

Note: Our curved plywood press can be used in the field of musical instrument manufacturing. For example, it can be used for wood bending works of guitar, piano, loudspeaker box, etc. In particular, it can be used for bonding of guitar soundboard, upper and lower face, etc.

| Model | |||

| Main voltage | 3 phase 380V, 50Hz or customized | ||

| Output power | 30KW-50KW | ||

| Working table size | 2000×1000mm | 2500×1300mm | 2500×1300mm |

| All working table sizes can be customized | |||

| Pressure | 120T | 150T | 240T |

| Output type | Two sets of RF press share one RF generator (shift to work) | ||