Meltblown Line

The meltblown line is used for the production of medical grade PP meltblown nonwovens with high filtration efficiency. This mask production equipment is available equipped with single or twin screw extruder. Different auxiliary equipment can be configured according to the production requirements, including plunger type screen changer, vacuum packaging system, metering pump, spinneret and winding machine.

The first production step is to feed the polypropylene PP raw material, mixed with a certain proportion of free radical initiator (DCPD), lubricant (Erucyl amide) and antioxidant, into a feeding inlet of a parallel twin screw extruder to be compounded, to get a ultra-high melt index MFI 1500 which is suitable for the raw material to make mask fabric by a melt-blown process, referred to as the high melt index PP melt-blown material. Our company can provide users with detailed formula percentage of compounding PP melt-blown material, which is free of charge.

According to the different output requirements, our company can provide compounding lines equipped with different twin screw extruder with L/D52~56. Each compounding line is equipped with a non-stop plunger type screen changing system with easy operation and extremely high filtration efficiency, and a vacuum packaging system, etc.

Technical Parameters of Twin Screw Extruder| Model | Screw O.D | L/D | Screw Speed(rpm) | Motor Power (kw) | Capacity(kg/hr) |

| SHJ-M-35 | 35.6 | 52~56 | 600/900 | 45~75 | 150~250 |

| SHJ-M-52 | 51.5 | 52~56 | 600/900 | 75~132 | 250~600 |

| SHJ-M-65 | 62.4 | 52~56 | 600/900 | 90~250 | 600~1000 |

| SHJ-M-75 | 71.0 | 52~56 | 600/900 | 200~315 | 1000~1600 |

Twin screw extruder especially for compounding high MFI 1500 PP raw material

Twin screw extruder especially for compounding high MFI 1500 PP raw materialThe second production step is to feed PP meltblown material mixed with a certain stabilizer, whitening agent and masterbatch, into a feeding inlet of a single screw extruder. Working with auxiliary devices such as screen, metering pump, spinneret, and winder, PP melt-blown fabrics with different widths are manufactured.

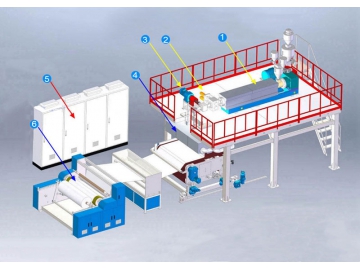

The layout of the production process is shown as follows:

- Single extruder

- Screen changer

- Meter pump

- Spinneret

- Control cabinet

- Winding machine

Schematic diagram of meltblown line for the production of PP meltblown fabrics with a high melt flow index

According to the different widths of the meltblown fabric and the different output, our company can provide different single-screw extruders with L/D30~33, and different auxiliary machines can be configured according to different requirements of users.

Technical Parameters of Single Extruder| PP Meltblown Cloth Width | Daily Capacity | Single Extruder Model |

| 600mm | 180kg | SJ-45/33 |

| 800mm | 300kg | SJ-55/33 |

| 1600mm | 1500kg | SJ-90/33 |

| 2400mm | 2500kg | SJ-105/33 |

| 3200mm | 4000kg | SJ-135/33 |