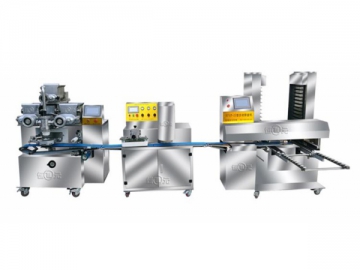

Scratch Card Production Line

Scratch Card Production Line

Our scratch card production line is suitable for producingcards and other flat objects that require a scratch-off-label to cover PINs, codes, etc.

Our complete unit of card production equipment can carry out the following functions:card feeding, inkjet-printing, imprinted data verification, PIN covering withscratch-off-ink, and card collecting, etc.

Applications:

As a result of its reliable performance and simple operation, our scratch cardproduction line is an ideal equipment for cardmanufactures serving in the telecommunications industry, mobile communicationsindustry, banks, and retail industry, etc.

The list of card productionmachines in the scratch card production line:

1. Sheet laminator

2. Die cutting machine

3. Code printing and labeling machine

4. Card packing machine (optional)

Features of Scratch Card Production Line (Solution I): Code printing & Labeling Machine with inspection system Flowchart: Features of Scratch Card Production Line (Solution II): Solution III for Scratch Card Production Line Personalize system This scratch card production equipment has powerful data processing capabilities with outstanding performance, high output capacity, and flexible configuration, etc. High levels of data security can also be guaranteed in this scratch card personalization system. Features of Scratch Card Personalization System: Outline designed: *For continuous improvement, the machines are subject to change without prior notice

Purpose: To finish the following steps in one-stop: piece by piece feeding of the cards from a loading tray, printing user identifications and PINs on cards by an inkjet printer (a separate item from the labeler), covering PINs with scratch off labels, and finally collecting finished cards.

1. Has a user-friendly design with an interactive touch-screen control panel to offer a convenient and straight forward operation.

2. A servo motor is installed in our labeling machine to carry out high precision labeling at high speeds.

3. Our scratch card production line is suitable for producing both standard CR80 cards and non-standard cards. Standard CR80 cards may run along the long side or along the short side, depending on suitability.

4. This card production equipment can store 50 sets of labeling parameters. This facilitates easy changeover between different labeling jobs by simply switching the pre-set labeling parameters.

5. Automatic card batching function is optional. It allows cards to be separated in batches of prescribed quantities, for easy card collection and packaging.

6. Designed with a compact and elegant structure, our scratch card production line is easy to install and maintain.

7. Data printing software with an encryption function is optional. It can work well with inkjet printers, with the ability to control two inkjet print heads simultaneously.

8. English and Chinese menu for set up configurations are both available.

9. During the labeling process, our scratch card production line effectively avoids leaving cards unlabelled due to the presence of an alarm system when such an error occurs.

10. Sand-glass traction roll is used in the label traction unit, to ensure that the labels are firmly gripped.

11. World-leading electrical components help ensure the long term stability and reliability of our machine.Cards Material PVC, Paper Cards Size (Length)50-110 × (Width)50-88 × (Thickness)0.3-1.2 mm or Standard CR80 Card Cards Loading Quantity Max. 500pcs each time (Standard 0.76mm thickness) Labeling Precision ±0.4mm (across movement direction)±1.0mm (along movement direction) Maximum Capacity 300 pcs/min (CR80 standard cards) (depending on cards sizes) Power Consumption 220VAC±5% 50Hz 0.85Kw Weight Approximately 250 Kg

Purpose: To finish the following steps in one-stop: feeding cards piece by piece from the loading tray, printing user identifications and PINs on cards using an inkjet printer (a separate item from the labeling machine), printing inspection using a vision inspection system, covering PINs with scratch off labels, and finally, collecting finished cards.

Separate and feed cards → data imprinting by inkjet printer→ imprinted data verification → rejection of incorrect cards → covering PIN with scratch-off-layer →collection of scratch cards.

1. Our scratch card production line is suitable for producing both standard CR80 cards and non-standard cards. Standard CR80 cards run along the long side or along the short side, depending on suitability.

2. Its design is user-friendly, with an interactive touch-screen control panel that offers convenient and straight forward operation. There are plenty of on-screen help functions and alarms.

3. Vision inspection system of our scratch card production equipment is acquired from the US.

4. Industrial computers are responsible for controlling data imprinting and verification processes.

5. High security is guaranteed by user authority control and on-site data encryption.

6. There is automatic re-print for rejected cards upon inspection.

7. Data printing software with the function of encryption is optional. It can work with inkjet printers to offer flexibility to our customers. It has the ability to control two inkjet print heads simultaneously.

8. During application of the scratch-off-layer, our scratch card production line can effectively avoid leaving out some cards unlabeled due to the presence of a lack-of-label alarm and missing-label stop function.

9. Sand-glass traction roll is installed in the label traction unit, for firm gripping of labels and precision in performance.

10. All electrical components of our scratch card production equipment are of internationally renowned brands to ensure long term stability and machine reliability.Cards Size (Length)50-110 mm× (Width)50-88 mm× (Thickness)0.3-1.2 mm or Standard CR80 Card Cards Loading Quantity Max. 500pcs each time (Standard 0.76mm thickness) Labeling Precision ±0.4mm (across movement direction) ±1.0mm (along movement direction) (other than errors from cards or labels) Inkjet Printing Inspection ErrorⅠ: Wrong-acceptance (pass a wrong card) less than 0.01% ErrorⅡ: Wrong-rejection (reject a right card) less than 2% Maximum Capacity 200 pcs/min (CR80 standard cards) (depending on cards sizes) Air consumption 0.6Mpa Power Consumption 220VAC±5% 50Hz 0.75Kw

This scratch card production line is an integrated system suitable for the personalization of cards with PINs. It can achieve card feeding, printing of personalized information and PINs, printed data inspection, PIN covering with scratch-off-ink, and card collection, etc. in just one-stop. It is regularly used by scratch card manufacturers, serving China Telecom, Unicom, and more.

1. This scratch card production line is suitable for different card materials, such as PVC and paper, etc.

2. The machine can produce both standard and non-standard cards.

3. Hologram or anti-counterfeit labels can be put on cards through our labeling machine.

4. Machine vision devices acquired from US ensure accurate data-printing. Full inspection on all printed-data further improves data accuracy.

5. Modular design to allow upgrade flexibility.

6. High speed operation enables our scratch card production line to have high production efficiency. The maximum production speed could be 10,000 cards per hour, depending on the data inspection function.

7. User friendly interactive touch-screen control panel enable us to operate the machine more conveniently and easily.

8. Full inspection on PIN coverage further improves production reliability and data security.

9. Manual operations are minimized. A protection cover is used to facilitate full enclosure, guaranteeing data security.

10. Rejected cards will be recorded for reprinting.

11. World-leading inkjet printers are used to offer maximum printing flexibility. Image, Domino, Video jet, Linx, and Hitachi inkjet printers are regularly adopted for our scratch card production lines.

12. Stainless steel or aluminium machine frames keep off rust, and are easy to maintain.Card size 45-110 mm (Length) x 40-120 mm (Width) x 0.3-1.2 mm (Thickness) or CR80 card Load capacity of Feeding Module 500 pcs. (thickness: 0.76mm) Speed (with inkjet printing inspection) Labeling: 10,000pcs/hour (CR80 cards) Hot-stamp: 8,000pcs/hour (CR80 cards) Inkjet Printing Inspection 26~45 digits/codes Inkjet Printing Inspection Error Level Error I (missed fault) < 1 per mil. Error II (mis-reject) < 2% Labeling Precision ± 1mm(along movement direction) ± 0.5mm(across movement direction) Scratch-off coverage inspection Positioning error (< /- 1.5 mm) Inspection reliability > 99% Surface integrity error (1.0mm x 1.0mm spot) Inspection reliability > 99% Power source 220VAC, 50 Hz, 3.5 KW Air pressure 0.6 Mpa Environment requirements Ambient temperature 0~50 °C Relative Humidity: 15~90% (w/o condensation) Weight Approximately 1,000Kg (varying in accordance with optional equipment you have selected) Footprint Approximately 0.7m(W) x 6m (L) (varying in accordance with optional equipment you have selected)

Founded in 1985, Our company is anexperienced scratch card production line supplier and manufacturer. All ourproduction lines are CCC, ISO and CE certified. They have been exported to

In addition to scratch card production lines, we can also produce IC cardproduction lines and card packing equipment, etc. If you are interested in ourcard production equipment, please contact us immediately!