Get in touch with us

Hydraulic Guillotine Shearing Machine

Features

- All steel welded structure with treatment of stress relief, providing excellent rigidity and stability;

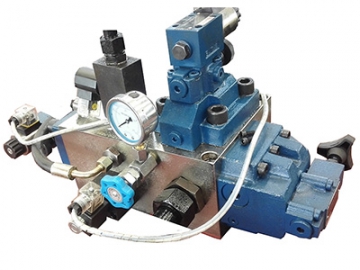

- Adopting advanced integrated hydraulic system increases the reliability and stability;

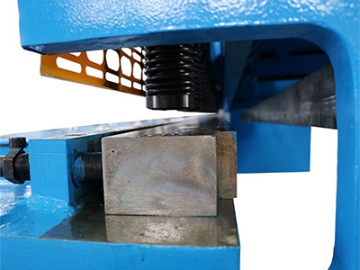

- Triple support rolling guide rail is used to eliminate the gaps of the support, enabling the shearing quality to be guaranteed;

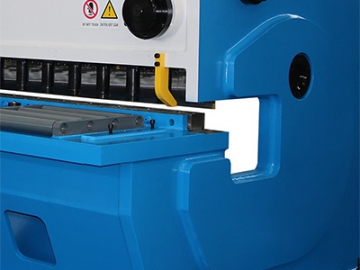

- Gap between shear blades is electrically adjusted in an accurate, quick and easy way;

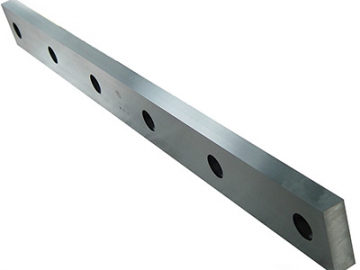

- Shear blades are rectangular-shaped with four cutting edges, offering a prolonged service life;

- Shearing angle is adjustable to minimize deformation of workpieces, enhancing the product quality and cutting speed;

- Upper blade holder is designed with an inward tilting structure, which can assist in material collection;

- With functions of sectional shearing and cut to length;

- Power back gauge with digital readout;

Applications

Details

Gear pump

Gear pump  E21S control system

E21S control system  Hydraulic valve

Hydraulic valve  Hold down pad

Hold down pad  Foot pedal

Foot pedal  Alloy steel metal shear blade

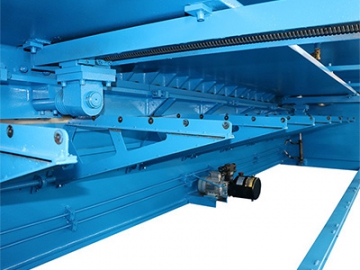

Alloy steel metal shear blade  Triple support rolling guide rail

Triple support rolling guide rail  Blade holder

Blade holder  Hydraulic cylinder

Hydraulic cylinder  NC controlled back gauge

NC controlled back gauge

Optional configurations

Cooling system

Cooling system  Back gauge lifting mechanism

Back gauge lifting mechanism  Deep throat

Deep throat  Pneumatic sheet support system

Pneumatic sheet support system

Specifications

| No. | Model(QC11Y) | 6x2500 | 6x3200 | 6x4000 | 6x6000 | 8x2500 | 8x3200 | 8x6000 |

| 1 | Shearing thickness (mm) | 6 | 6 | 6 | 6 | 8 | 8 | 8 |

| 2 | Shearing width (mm) | 2500 | 3200 | 4000 | 6000 | 2600 | 3200 | 6000 |

| 3 | Cutting plate tensile strength N/mm3 | 450 | 450 | 451 | 452 | 453 | 454 | 455 |

| 4 | Shearing angle (°) | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 |

| 5 | Back gauge range (mm) | 20-600 | 20-600 | 20-600 | 20-600 | 20-600 | 20-600 | 20-800 |

| 6 | Blade length (mm) | 2600 | 3300 | 4100 | 6150 | 2600 | 3300 | 6150 |

| 7 | Throat depth (mm) | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| 8 | Blade material | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si |

| 9 | Main motor power (KW) | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 15 |

| 10 | Stroke (n/min) | 16-35 | 14-35 | 10-30 | 10-30 | 14-30 | 12-30 | 8-20 |

| 11 | Length (mm) | 3150 | 3860 | 1630 | 6680 | 3170 | 3870 | 5800 |

| 12 | Width (mm) | 1500 | 1810 | 1900 | 2200 | 1700 | 1810 | 2150 |

| 13 | Height (mm) | 1830 | 1750 | 1800 | 2500 | 1700 | 1780 | 2500 |

| No. | Model(QC11Y) | 10x2500 | 10x3200 | 10x6000 | 12x2500 | 12x3200 | 12x4000 | 12x6000 |

| 1 | Shearing thickness (mm) | 10 | 10 | 10 | 12 | 12 | 12 | 12 |

| 2 | Shearing width (mm) | 2600 | 3200 | 6000 | 2500 | 3200 | 4000 | 6000 |

| 3 | Cutting plate tensile strength N/mm3 | 450 | 450 | 450 | 150 | 150 | 450 | 450 |

| 4 | Shearing angle (°) | 0.5-2.0 | 0.5-2.0 | 0.5-1.5 | 2.5-2.0 | 0.5-2.0 | 0.5-2.0 | 0.5-2.0 |

| 5 | Back gauge range (mm) | 20-600 | 20-800 | 20-1000 | 20-800 | 20-800 | 20-8000 | 20-1000 |

| 6 | Blade length (mm) | 2600 | 3300 | 6150 | 2600 | 3300 | 4100 | 6150 |

| 7 | Throat depth (mm) | 80 | 80 | 80 | 80 | 80 | 80 | 100 |

| 8 | Blade material | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si |

| 9 | Main motor power (KW) | 15 | 15 | 22 | 15 | 15 | 15 | 30 |

| 10 | Stroke (n/min) | 10-25 | 9-25 | 6-15 | 9-25 | 9-25 | 6-20 | 6-15 |

| 11 | Length (mm) | 3200 | 3880 | 6800 | 3270 | 3880 | 4720 | 6880 |

| 12 | Width (mm) | 1730 | 2000 | 2350 | 1900 | 2000 | 1850 | 2380 |

| 13 | Height (mm) | 1750 | 2200 | 2800 | 2120 | 2200 | 2500 | 2700 |

| No. | Model(QC11Y) | 12x8000 | 12x9000 | 16x2500 | 16x3200 | 16x4000 | 20x2500 | 20x3200 |

| 1 | Shearing thickness (mm) | 12 | 12 | 16 | 16 | 16 | 20 | 20 |

| 2 | Shearing width (mm) | 8000 | 9000 | 2500 | 3200 | 4000 | 2500 | 3200 |

| 3 | Cutting plate tensile strength N/mm3 | 450 | 450 | 450 | 450 | 450 | 450 | 450 |

| 4 | Shearing angle (°) | 0.5-2.0 | 0.5-2.0 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-3.0 | 0.5-3.0 |

| 5 | Back gauge range (mm) | 20-1000 | 20-1000 | 20-800 | 20-800 | 20-800 | 20-1000 | 20-1000 |

| 6 | Blade length (mm) | 8100 | 9150 | 2600 | 3300 | 3300 | 2600 | 3300 |

| 7 | Throat depth (mm) | 100 | 100 | 80 | 80 | 80 | 100 | 100 |

| 8 | Blade material | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si |

| 9 | Main motor power (KW) | 45 | 45 | 22 | 22 | 22 | 30 | 30 |

| 10 | Stroke (n/min) | 6-20 | 5-15 | 9-20 | 8-20 | 8-15 | 7-20 | 6-20 |

| 11 | Length (mm) | 9100 | 10100 | 3320 | 412 | 4760 | 3300 | 4180 |

| 12 | Width (mm) | 2800 | 3000 | 2100 | 1980 | 1900 | 2050 | 2100 |

| 13 | Height (mm) | 3400 | 3900 | 2200 | 2300 | 2560 | 2440 | 2540 |

| No. | Model(QC11Y) | 16x6000 | 16x8000 | 16x9000 | 16x12000 | 20x6000 | 20x8000 | 20x10000 |

| 1 | Shearing thickness (mm) | 16 | 16 | 16 | 16 | 20 | 20 | 20 |

| 2 | Shearing width (mm) | 6000 | 8000 | 9000 | 12000 | 6000 | 8000 | 6000 |

| 3 | Cutting plate tensile strength N/mm3 | 450 | 450 | 450 | 450 | 450 | 450 | 450 |

| 4 | Shearing angle (°) | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 1.0-2.5 | 0.5-3.0 | 1.0-2.5 | 0.5-3.0 |

| 5 | Back gauge range (mm) | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 |

| 6 | Blade length (mm) | 6150 | 8200 | 12120 | 6150 | 8200 | 6150 | |

| 7 | Throat depth (mm) | 100 | 100 | 100 | 150 | 100 | 100 | 100 |

| 8 | Blade material | Cr12MoV | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si |

| 9 | Main motor power (KW) | 37 | 55 | 55 | 2*45 | 55 | 2*37 | 55 |

| 10 | Stroke (n/min) | 6-15 | 5-15 | 4-15 | 3-12 | 4-15 | 4-15 | 4-15 |

| 11 | Length (mm) | 6880 | 9200 | 10200 | 13220 | 6880 | 9200 | 6880 |

| 12 | Width (mm) | 2480 | 3000 | 3600 | 4300 | 2650 | 3400 | 2650 |

| 13 | Height (mm) | 3000 | 3800 | 4200 | 5800 | 3375 | 3800 | 3375 |

| No. | Model(QC11Y) | 20x13000 | 25x2500 | 25x3200 | 25x6000 | 25x10000 | 30x6000 | 16x6000 |

| 1 | Shearing thickness (mm) | 20 | 25 | 25 | 25 | 25 | 30 | 16 |

| 2 | Shearing width (mm) | 13000 | 2500 | 3200 | 6000 | 10000 | 6000 | 6000 |

| 3 | Cutting plate tensile strength N/mm3 | 450 | 450 | 450 | 450 | 450 | 450 | 450 |

| 4 | Shearing angle (°) | 1.0-2.5 | 1.0-3.5 | 1.0-3.5 | 1-3.0 | 1-2.5 | 1-3.0 | 0.5-2.5 |

| 5 | Back gauge range (mm) | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 |

| 6 | Blade length (mm) | 121000 | 2600 | 3300 | 6150 | 10250 | 6125 | 6150 |

| 7 | Throat depth (mm) | 100 | 100 | 100 | 1000 | 1000 | 1000 | 100 |

| 8 | Blade material | Cr12MoV | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si | 6CrW2Si |

| 9 | Main motor power (KW) | 2*55 | 37 | 37 | 55 | 2*55 | 2*37 | 45 |

| 11 | Stroke (n/min) | 3-10 | 6-15 | 5-15 | 3-12 | 4-14 | 3-12 | 6-15 |

| 12 | Length (mm) | 14380 | 3300 | 4200 | 7200 | 11680 | 7300 | 6850 |

| 13 | Width (mm) | 4300 | 2400 | 2400 | 3000 | 4000 | 3800 | 2450 |

| 14 | Height (mm) | 6800 | 3050 | 3100 | 3850 | 5420 | 4200 | 3050 |

Related products

Send Message

Most Recent

More

Other Products

Videos