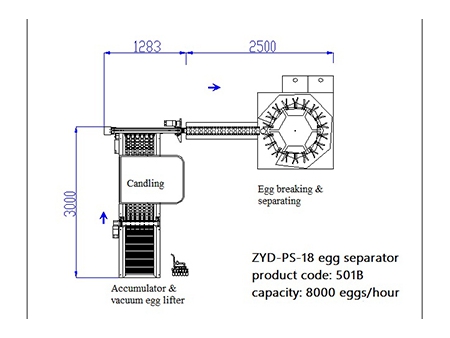

501B Egg Breaking and Separating Machine (8,000 EGGS/HOUR)

ZENYER 501B egg breaking and separating machine is designed to break eggs and separate yolks and egg whites with a maximum capacity of 8,000 eggs/hour.

This egg breaker can be used offline, or it can be attached to a ZENYER for a more productive assembly line. The machine body is made of 304 stainless steel, and meets all food processing safety requirements. It is simple and easy to use and clean. This model is applicable to large scale enterprises such as farms, bakeries, restaurant suppliers and more.

| Product name | Egg separator |

| Product code | 501B |

| Model | ZYD-PS-18 |

| Capacity | 8,000 eggs/hour |

| Materials | Stainless steel |

| Power* | 0.4 KW |

| Voltage* | 220V, 50HZ, single phase |

| Dimension(L×W×H) | 3×1.13×1.4 M |

| Function | Breaking, separating egg whites and yolks |

The equipment is comprised of the feeding conveyor and spinning plate. The spinning plate contains 18 robotic arms with blades, 18 spoons for yolks, and 18 spoons for egg whites.

The separator is equipped with an auto feeding system, meaning users only need to place the eggs on the feeding conveyor, and the robotic arms will catch the eggs sent from the feeding line. Eggs will then be broken by the robotic arms, and the liquids will flow to the yolk spoons. Egg whites will be dropped by the spoons onto spoons in the lower level through a continuous vibration, while the egg yolk is retained by the spoon originally holding the white and the yolk.

The spinning and vibrating process only lasts for 4/5 round, and egg white spoons and yolk spoons will pour egg whites and yolks into corresponding containers. Eggshells are disposed during the last 1/5 of a round. Afterwards, a new round begins.

Eggs are vacuum lifted and loaded onto 6-row of the 605A accumulator by using the 602 vacuum egg lifter. This egg accumulator features candling to check for any leaking, dirty or cracked eggs. Then directs 6 lanes of eggs into 1 lane and transports them to the feeding conveyor of the egg cracking system.

It is also equipped with a candling cover and a mirror for better candling inspection.

The egg cracking system includes 18 robotic arms with 18 egg yolk and egg white spoons separately.

The robotic arms will catch the eggs sent from the feeding conveyor. Eggs will then be broken and split by the robotic arms, and the liquids will flow to the yolk spoons. Egg whites will be dropped by the spoons onto spoons in the lower level through a continuous vibration.

The spinning and vibrating process only lasts for 4/5 of a round, and egg white spoons and yolk spoons will pour egg whites and yolks into corresponding containers. Eggshells are disposed during the last 1/5 of a round. Afterwards, a new round begins.