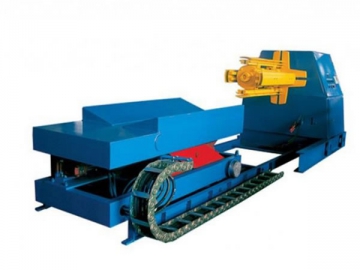

Uncoiler

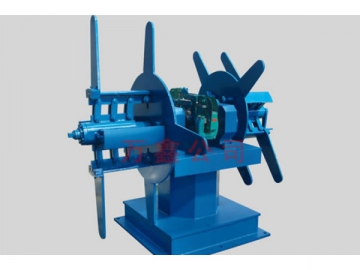

The hydraulic uncoiler is the specific machine for uncoiling metal materials. There are three or four rake fanning strips, which are connected by a dovetail groove then installed on the mandrel.

The end of the fanning strip has a radial slide installed that is capable of opening and shrinking in the radial direction in case it moves to the shaft.

The tail of the drum shaft connects to the rotatable cylinder. The cylinder piston rod drives the forward tetragonal shaft move along the shaft using a draw bar in the middle. The fanning then opens or shrinks to add to the overall diameter of the coiling block.

This machine can make stretch coils and deliver coil automatically. The speed is the same as the forming machine. The hydraulic uncoiler is a matching machine for colored steel equipment. In order to save human resources and lower labor costs, the machine works best with colored steel mold machines and stackers, in order to form a complete production line.

This machine is composed of a feeding main machine, the hydraulic station, and CNC control system.

Technological Process:

Uncoiling---Feeding---Leveling---Punching---Rool Forming---Cutting---Products Collecting

Main technical specifications of hydraulic decoiler:

1. Installation size: 2700mm*1750mm*1700mm

2. The coil width: ≤1250 mm

3. Coil inside diameter: 480-510 mm

4. Productivity: 0-15 m/min

5. Main motor power: 3 KW

6. Hydraulic unit power: 3 KW

7. Electric control system: PLC vector inverter

8. Tolerate weight: max 5 tons