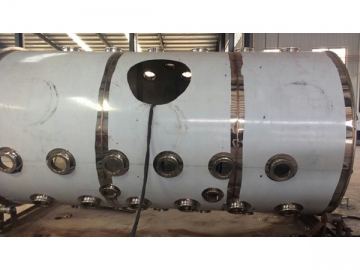

PVD Coating Equipment (for Ceramic Tiles and Ceramic Products)

Benefits of PVD Coating Equipment

PVD coating equipment makes quick work of coating ceramic tiles and wares with a thin layer of gold or silver. The resultant silver or golden coating imparts an attractive shine to the ceramics. This vacuum coating system is the machine of choice when it comes to manufacturing high-end ceramic products.

Features of PVD Vacuum Coater

Advanced PLC system comes with vacuum gauge and flow controller. Gas pumping speed is adjusted by shifting gears via a computer control system. A total of 4 heating tubes are mounted to the side of the vacuum chamber. PLD temperature controller keeps a constant temperature in the chamber.

Applications for Vacuum Coating Machine

Suitable for use in the manufacture of large metal hardware, ceramic products, glazed tiles, ceramics and large stainless steel plates.

| Model No. | ||||

| Vacuum Chamber Size | ф1500×1900 | ф2240×1700 | ф2300×2200 | ф2500×2400 |

| Air Pumping Speed | 1×105 Pa~3×10-3 Pa≤20min | |||

| Maximum Vacuum Level | ≤1×10-3 Pa | |||

| Auxiliary Equipment | KT-1000 / 2X-30 /H-150X2 / ZJP-600×1 | KT-1000 ×2-2X-30x2 /H-150X4ZJP-1200×2 | ||

| Transmission | Planetary gear (for rotation and revolution) (No. of rotary shafts: 4/5/10 /12, as per customer requirements) | |||

| Heating method | Drying oven | |||

| No. of Ceramic Tiles | 1500×1900, model no.: 320, 8 rotary shafts, 96 tiles; 2240×1700, model no.: 320, 12 rotary shafts, 144 tiles; model no.: 630, 4 rotary shafts, 24 tiles; model no.: 800, 4 rotary shafts, 8 tiles; 2300×2200, model no.: 320, 12 rotary shafts, 216 tiles; model no.: 630, 4 rotary shafts, 48 tiles; model no.: 800, 4 rotary shafts, 16 tiles; 2500×2400, model no.: 320, 10 rotary shafts, 300 tiles; model no.: 630, 5 rotary shafts, 60 tiles; model no.: 800, 4 rotary shafts, 24 tiles | |||

| Gas Pumping System | Flow rate controller | |||

| No. of Cathodic Arcs | 18-24 | 24-32 | ||

| Working Mode | Semi-automatic PLC or fully automatic PC PLC | |||

| Working Gas (Gaseous Environment) | Ar , N2 | |||

| Total Power | 120KW | 160KW | ||

| Compressed Air | 0.4~0.8MPa | |||

| Water Cooling System | Water Pressure/Water Temperature≤25 ℃ /≥0.25MPa (Prepared by clients) | |||

PVD Coating Samples

.jpg)