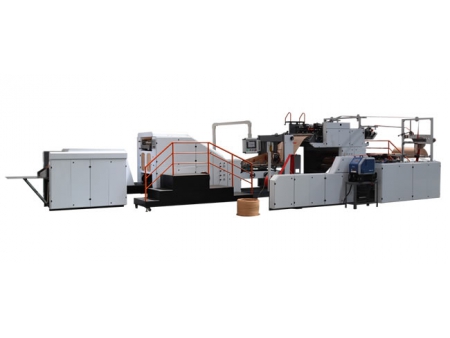

Twisted Handles Block Bottom Bag Making Machine

This bag making machine is designed for the automatic production of paper shopping bags with twisted handles, which is an ideal choice for bag making operations looking to minimize operating costs without sacrificing quality.

| Model | ZD-F200Q | ZD-F260Q | ZD-F350Q | ZD-F450QX | ZD-F450Q | ZD-F550Q |

| Roll paper width | 280-650 mm | 360-910 mm | 420-1090 mm | 670-1370 mm | 650-1330 mm | 670-1670 mm |

| Max. diameter of paper roll | φ1500 mm | φ1500 mm | φ1500 mm | φ1500 mm | φ1500 mm | φ1500 mm |

| Roll core diameter | φ76 mm | φ76 mm | φ76 mm | φ76 mm | φ76 mm | φ76 mm |

| Paper gram | 50/65-150g/㎡ | 50/65-150g/㎡ | 60/80-150g/㎡ | 70/80-150g/㎡ | 80/90-150g/㎡ | 80/90-150g/㎡ |

| Paper bag width | 80/110-200 mm | 100/130-260 mm | 130/180-350 mm | 230-450 mm | 230-450 mm | 240-540 mm |

| Cut off length | 190-(370mm with handle height) | 260-(530mm with handle height) | 260-(530mm with handle height) | 280-(630mm with handle height) | 380-(780mm with handle height) | 380-(770mm with handle height) |

| Gusset width | 50-110mm | 65-180mm | 65-180mm | 80-220mm | 90-200mm | 80-280mm |

| Handle height | 70-100mm | 70-100mm | 90-120mm | 90-120mm | 90-120mm | 90-120mm |

| Handle rope diameter | φ2.5-5 mm | φ3-5 mm | φ3-5.5 mm | φ3-6 mm | φ3-6 mm | φ4-6 mm |

| Handle patch length | 95mm | 114mm | 152mm | 190mm | 190mm | 190/202 mm |

| Handle patch width | 42.5-50 mm | 42.5-50 mm | 42.5-50 mm | 42.5-50 mm | 42.5-50 mm | 42.5-50 mm |

| Handle hole distance | 47.5mm | 57mm | 76mm | 95mm | 95mm | 95/101 mm |

| Roll paper diameter (patch) dia | φ1200 mm | φ1200 mm | φ1200 mm | φ1200 mm | φ1200 mm | φ1200 mm |

| Handle patch width | 85-100 mm | 85-100 mm | 85-100 mm | 85-100 mm | 85-100 mm | 85-100 mm |

| Paper gram of handle patch | 80-150 g/㎡ | 80-150 g/㎡ | 80-150 g/㎡ | 80-150 g/㎡ | 80-150 g/㎡ | 80-150 g/㎡ |

| Max. production speed | 100-150 bags/min | 100-150 bags/min | 100-150 bags/min | 100-140 bags/min | 90-130 bags/min | 80-130 bags/min |

| Total power | 30 KW | 30 KW | 30 KW | 30 KW | 30 KW | 30 KW |

| Machine weight | 15500 KG | 17500 KG | 18500 KG | 19500 KG | 20500 KG | 21500 KG |

| Overall dimensions ( L*W*H ) | 12500*5500*2500 mm | 13500*5600*2500 mm | 13500*5700*2500 mm | 14500*5800*2500 mm | 15000*6000*2500 mm | 15500*6200*2500 mm |

The handles making part forms the cord and paper roll to handles, which are delivered to handle pasting section to perforate. The plain or printed paper and glue are fed to main machine for side gluing, tube forming, cut-off, bottom creasing, bottom gluing, bag forming and bag collection. The Mitsubishi electrical control system, servo motor and drive ensure its high precision and stability, simple maintenance and high efficiency.

- FEEDING UNIT

The roll paper fixed on the air expanding mandrel can be fed by swing arm which is equipped with lifting hydraulic system. With an alarm function, the feeding unit will sound alarm when there is no paper feeding. Improved surface smoothness of the paper during the feeding is achieved due to the web guide and uniform tension control. Paper rolls can be easily changed by pressing a button.

- HANDLE MAKING UNIT

It pastes twisted paper ropes and paper together to create a handle.

- HANDLE PASTING UNIT

The handle pasting machine can automatic pasting the twisted handle into the required position of bag body with the use of glue and then presses it firmly on the bag body before pre-creasing.

- BAG FORMING UNIT

Form the paper with patches and side glue into the tube; and cut into separate pieces based on the settings. Afterwards, these separate tube will be sent to the drum to open the four corners, then bottom gluing, sealing and form the square shape consequently.

- BAG COLLECTING UNIT

Compress the bags and outlet the bags. The number of paper bags can be processed and presented by the automatic collection and counting system.