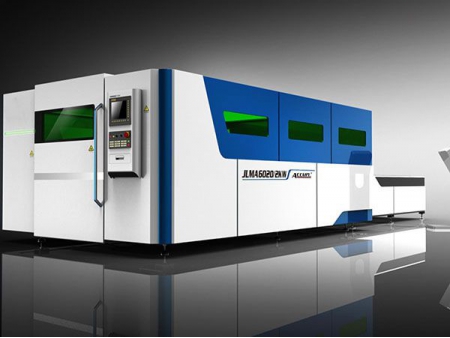

3kW Fiber Laser Cutting Machine

Request a Quote

with High Power Fiber Laser

ACCURL® fiber laser power source of the ECO series is an all-solid-state laser. This technology reduces the maintenance requirements and offers the lowest running cost with wall plug efficiency of 30% and without the need of any laser gas. When the application requires a material of broader spectrum and the maximum thickness range is limited, the fiber laser is the ideal solution. Compared with other CO2 lasers with same laser power, it cuts faster at lower cost.

Advantages

- Acceleration speed: 19.6 m/s2 (2G).

- Maximum simultaneous positioning speed: 160m/min.

- Precision: - 0.05 mm.

- Energy efficiency: greatly reduces the power consumption.

- Excellent cutting quality for metal sheets of small thickness and medium thickness.

- IPG Resonator. Power output from 1kw to 6kw.

- Precitec cutting head with power output of 3kw.

- Precitec HP cutting head for power output over 3kw.

- Fully enclosed and cabined to protect the operator to the greatest extent possible.

- Effective high and low pressure gases exchange system.

- Capacitive sensor, high pressure cutting head.

- ECO cutting parameter table.

- Pre-cut film protector.

- Automatic mechanical nesting power output control function (edges, start-ups).

- Automatic time and unit cost calculation function.

- Network connection from external.

- Automatic table exchanger (included in the models of this series).

- Smoke extraction (included in the models of this series).

- 3-point reference sensor (sheet metal rotation detector).

- Piercing sensor. Collection of work pieces and trimmings.

- Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

Specifications

| Model | ECO-FIBER-2040 /IPG 3KW Fiber |

| Transmitting system | Precise ball screw transmitting |

| Laser power | 3000W |

| Working table | 1500*3000 (mm) |

| Max running speed | 120/min |

| X/Y location precision | 0.05mm/m |

| Power supply | 380v 50Hz |

| X/Y repeated location precision | ±0.03mm |

| Machine gross power | < 20KVA |

| Running temperature | 0°C-40°C |

| Running humidity | < 90% |

| Max. acceleration speed | 1.5G |

| Machine body size | 7900*2950*1900 (mm) |

| Applied materials | Thin mild steel, stainless steel and other kinds of metallic sheets; |

| Type | IPG | IPG | IPG | IPG | |

YLR-1 KW | YLR-2 KW | YLR-3 KW | YLR-4 KW | ||

| Output Power | 1000 W | 2000 W | 3000 W | 4000 W | |

| Material | |||||

| Mild steel | 10 mm | 16 mm | 20 mm | 25 mm | |

| Stainless steel | 4 mm | 8 mm | 12 mm | 15 mm | |

| Aluminum | 3 mm | 6 mm | 12 mm | 12 mm | |

| Brass | 2 mm | 3 mm | 8 mm | 8 mm | |

| Copper | 2 mm | 3 mm | 8 mm | 8 mm | |

| Galvanized steel | 3 mm | 4 mm | 10 mm | 10 mm | |

Detailed Pictures