Crushing and Screening Units

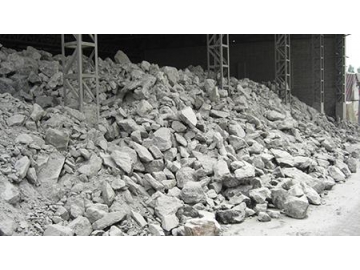

During the procedure of crushing and screening units, big ores are crushed into small-sized ones, ready for grinding and separation procedure.

Crushing and screening units consist of crusher, elevating conveyor, dust removal system, etc.

Gypsum ores are fed into hopper by forklift, sent to crusher via frequency conversion vibration, crushed until the sizes are suitable for grinding. Finished materials are sent to elevating conveyor, conveyed to raw silo.

Silos are equipped with sensors, to detect the stage of broken particle pile in the silo, data is sent to PLC, and responds are delivered in time, to control on/off of the crushing system.

Two types of crushers optional: jaw crusher and hammer crusher, can be used both individually or in combination.

- Jaw Crusher

Breaking by crushing, able for works on various ores and large solid materials with a strength under 320Mpa. The inlet range is 200mm-above 600mm, according to the size of material. - Hammer Crusher

Breaking by crashing, works on ore with medium hardness, sized between 600-1800mm. Finished size is under 25mm. - Silo Belt Weigher

Quantity of crushed material sent to belt weigher and running speed of belt weigher are adjustable according to output.