Zinc Pumps

Zinc pumps use the centrifugal force generated by the high speed vane to convey melted zinc, usually to a higher place. They are necessary equipment for the regular maintenance and leakage repairing of the galvanizing kettle, as well as the flooded galvanizing method. As zinc pumps for galvanizing line, the main parts of the pumps, like vane wheel, shell, and seal cartridge, etc. are made of special steel alloy which can resist the corrosion of the zinc. So the pump can effectively control the flow rate, temperature decline, and the thermal expansivity, meeting your requirements for long-term operation of the galvanizing equipment.

Parameter of the zinc pumps| Model | Motor power (kW) | Lifting height (m) | Pipe diameter (mm) | Flow rate (ton/hour) |

| p4.0 | 4 | φ65 | 30 | |

| p5.5 | 5 | φ88 | 60 | |

| p5.5 | 5 | φ96 | 100 | |

| p7.5 | 6 | φ136 | 180 |

Feature of the zinc pumps for galvanizing equipment

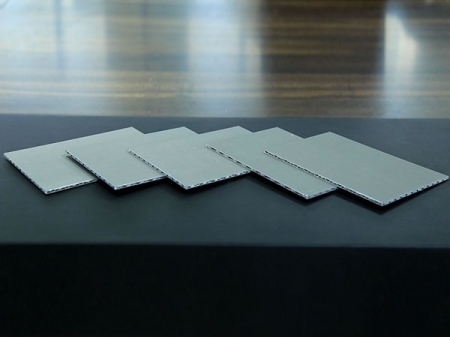

1. The vane wheel and shell of the pump are made of special steel alloy which is highly resistant to the corrosion of zinc. This kind of material is high temperature resistant and anti-wear, guaranteeing the long service life of the pump.

2. Long-clearance self-aligning bearings are adopted for better operational stability.

3. The vertical long transmission axle can ensure that the driving motor stay far from the heat source and work for a long time.

4. A hand wheel is available on the pump spindle, with which you can inspect the vane wheel and shell to avoid them being clogged by low temperature zinc at any time.