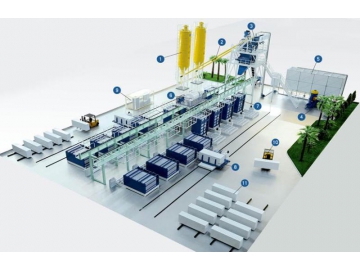

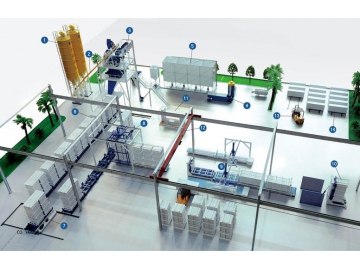

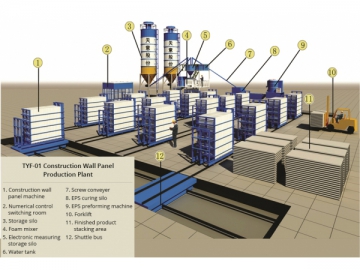

Horizontal Type EPS Light Weight Wall Panel Production Line

The horizontal insulated concrete wall panel production line mainly consists of batching system, mixing system, material transporting and feeding system, molding system, stacking system etc. This production line features high automation level.

The production line can provide higher yield and reduce operation difficulty by adopting vertical injection molding and horizontal demoulding. The machine is vertical so that the floor area is reduced.

Supporting equipment:

- Cement silo

- Screw conveyor

- Mixing system

- EPS pre-expander

- EPS silo

- Slip casting system

- Horizontal hydraulic molding machine

- Automatic movable stripper

- Control system

- Forklift

- Finished product stacking yard

horizontal insulated concrete wall panel production line adopts continuous discharging and mixing technology, so that it can effectively improve production efficiency. Meanwhile, it can solve the problem that continuous material feeding will cause nonuniform material separation.

Rate schedule of the horizontal insulated concrete wall panel production line:| Dimension of the finished wall panel | 3000/2440×610×75/90/100/120/150/180mm | |

| Yield of the wall panel of different thickness (once) | 75mm | 30 pieces |

| 90mm | 26 pieces | |

| 100mm | 24 pieces | |

| 120mm | 20 pieces | |

| 150mm | 16 pieces | |

| Compaction system cylinder stroke | 200mm | |

| Rotation cylinder stroke | 1500mm | |

| Motor power of the hydraulic pressure station | 4kw | |

| Machine dimension | Horizontal | 4600×3000×1850mm |

| Vertical | 4600×3000×3500mm | |

| Weight | 5.2T | |

Related products

Send Message

Most Recent

More

Other Products

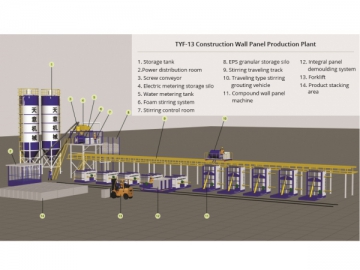

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com

Videos