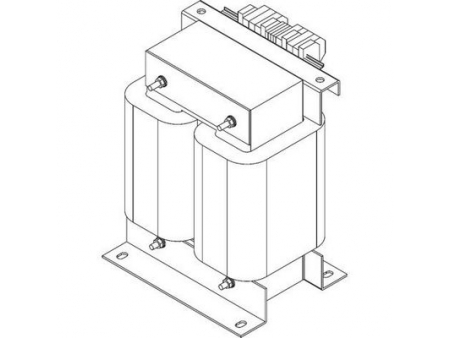

Isolation Transformer

Application

The Sikes' isolation transformer generates pure power for electrical devices. The transformer enjoys high interference resistance, and is widely applied in power transmission and distribution in metros, high buildings, airports, stations, docks, industrial enterprises, mining enterprises and tunnels.

Typical applications of the transformer include power generators controlling regular circuits, security lighting or signal lights, which are used in air-conditioners, machine tools and mechanical devices in electronic engineering enterprises, industrial enterprises and mining enterprises. The secondary winding of the transformer is not connected to the ground, consequently, no potential difference remains among any wire in secondary winding and the ground, ensuring safe use of the device, grouping the transformer into safe power generators. The product is also used in repairing and maintenance of machinery, in order to prevent lightnings and harmonics.

Specification

Power Range: 15kVA-1000kVA

Phase: single phase/three phase

Primary Voltage: 220V / 380V

Secondary Voltage: 380V / 220V

Frequency: 50/60Hz

Hyperbolic Positioning: conforming to DIN41307

Coils: varnished copper wires of level F/H, with primary and secondary current segregated

Protection Level: IP00 or customized by client specification

Insulation Level: level F/level H

Standards Conformed: EN61558-2-6

Feature

1. The isolation transformer features current segregation to ensure safe use.

2. Vacuum pressure varnishing is performed on the device to achieve satisfactory erosion resistance.

3. An embedded module of fault protection is customizable in the product.

4. Various combinations of input/output voltage can be chosen within the transformer.

5. High quality silicon lamination is used to manufacture the iron core of the transformer, resulting in high reliability, tiny size, light weight and competitive prices of the product.

6. Coils of the device are made up of composite insulation materials with high heat resistance, with scaffolding-free or foil winding techniques adopted for processing. Consequently, the device receives high electromagnetic endurance and an agreeable appearance.

7. Varnishing of different insulation levels are performed to the device, conforming to varied specifications. Such tooling of the device results in small noise, tiny magnetic leakage, stable capability of the product; besides, the influence of salt spray or mold on the transformer is significantly reduces.