3D Printing or Additive Manufacturing

3D printing is a cost-effective and efficient process for creating three dimensional solid objects by adding layers of materials using computer-aided design (CAD), so it is also referred to as additive manufacturing. In contrast to subtractive manufacturing processes that remove materials to create parts, 3D printing enables complex parts to be shaped using less material thereby saving significant manufacturing costs.

The applications for 3D printing are numerous. Typically, it is perfect solution for building prototypes and small batch production. That is because 3D printing can help improve product development process and shorten the time for working on complex designs.

- Consumer goods: shoes, housewares, furniture, glasses

- Industrial products: prototypes, manufacturing tools

- Dental products: dental molds, dentures, surgical guides, clear aligners

- Prosthetics: prosthetic limbs, orthotic braces

- Architecture: scale models, maquettes

- Archaeology & museum: reconstructing fossils, replicating historical artifacts

- Forensics: reconstructing evidence for forensic investigation and crime-solving

- Filming: movie props

- At Hongyan Hang we provide rapid prototyping service based on our 3D printing process, through which we are capable of helping you prototyping or manufacturing complex investment castings within a tight deadline, thus greatly shortening your overall development time.

- For single part or multiple parts manufacturing, we use combined processes of 3D printing and CNC machining for quick response to customer needs.

- For mass production of dozens or even hundreds of parts, we will help customer identify the best solution that is precisely oriented to the characteristics of product by appropriately using 3D printing, molding, sand casting, lost wax casting and other manufacturing processes.

Sand casting using 3D printing CNC precision machining technologies

3D printed 4-cylinder engine block 3D printed V-twin engine

3D printed electric motor housing

3D printed gearbox housing

3D printed transmission housing

- Metal Binder Jet 3D Printer

Brand: ExOne

Build volume: 800x500x400mm

Binder type: water-soluble binder

Accuracy: 0.050mm

Roughness: ≤ 3.2Ra

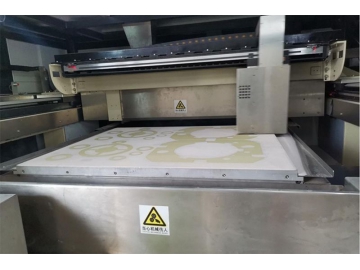

Supporting materials: stainless steel (316L, 17-4PH, 420), copper, zirconia, hydroxyapatite, calcium phosphate, silicon nitride, tungsten, nickel, aluminum, titanium, ceramic, cordierite, etc. - Light-curing Ceramic 3D Printer

Brand: 3DCeram

Build area: 600x600x300mm

Accuracy: 0.050mm

Roughness: ≤ 1.2Ra

Supporting materials: aluminum oxide, zirconium oxide (ZrO2 3Y, ZrO2 8Y) - Selective Laser Melting Machine

Brand: Additive Industries

Build volume: 420x420x400mm

Laser power: 500/1000W

Accuracy: 0.050mm

Oxygen concentration: ≤100ppm

Supporting materials: titanium, aluminum, steel, copper, nickel, etc. - Laser Cladding Machine

Brand: BeAM

Build volume: 1200x800x800mm

Laser power: 500/1000/2000W

Accuracy: 0.050mm

Supporting materials: steel, copper, nickel, aluminum, titanium, etc.