Plastic Injection Molding for Household Products

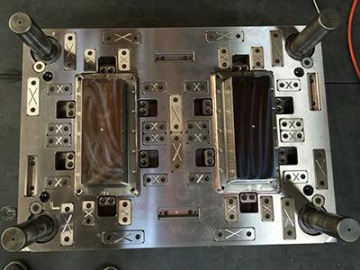

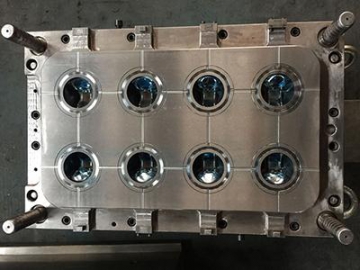

Plastic features a wide application range in our daily life, ranging from personal hygiene products, to toys, and everything in between. Because of that, we produce both hot runner and cold runner molds for the production of just about any plastic product our customers may need. According to product specifications, and customer injection molding machines, we offer multi-cavity molds, including 2 cavity molds, 4 cavity molds, 12 cavity molds, 64 cavity molds and so on.

Because plastic household products are generally inexpensive, and rapidly wear, they often need to be changed or upgraded, which is something we take into full consideration for production of all of our molds. We use an advanced hot runner system, which features a higher mold processing accuracy than a cold runner system. This ensures plastic products made using these molds have a smoother service. We then do everything possible to offer solutions that lower the mold manufacturing cost for our customers. Aero Mold has designed and manufactured dozens of different plastic injection mold types, so that customers can select from adjusting molds, and make any adjustments necessary. If none of our existing mold types meet your needs, we also offer mold customization services, all with a high efficiency and short development period.

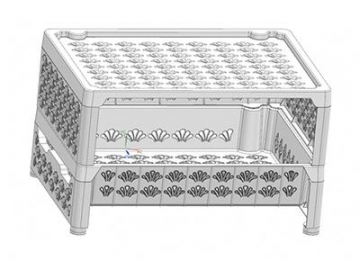

Sample Plastic Basket

Plastic Basket Plastic Storage Crate

Plastic Storage Crate Plastic Connector

Plastic Connector Plastic Bins

Plastic Bins Plastic Beer Crate

Plastic Beer Crate Clothes Plastic Storage Drawer

Clothes Plastic Storage Drawer Plastic Jar

Plastic Jar Translucent Plastic Basket

Translucent Plastic Basket Plastic Rattan Chair

Plastic Rattan Chair Plastic Basket with Handle

Plastic Basket with Handle Plastic Container with Spout

Plastic Container with Spout Plastic Laundry Basket

Plastic Laundry Basket Plastic Champagne Flutes

Plastic Champagne Flutes

- Mold base: Plastic mold steels of P20 and 2316 are used for the production of thin wall packaging molds, which avoids mold corrosion and water leaking through any loose connections.

- Mold core, mold cavity: Heat treated 2344 steel, S136 steel and other steels will undergo heat treatment to obtain a hardness of HRC 48-52. This design ensures a long mold life, and helps decrease the risk of mold rusting.

- Insert: Some inserts, such as the heated nozzle, are made using a heat treated S136 or 2083 steel. Not only that, but an insert installed on the top of the male mold's core uses BeCu (Beryllium Copper) instead of other materials, as BeCu is able to withstand the higher temperatures and poor heat dissipation found when inserts are located extremely close to the heated nozzle.

- If required, AERO MOLD can also manufacture thin wall packaging molds made of other materials.

PS Champagne Flutes Injection Mold, Complex Mold Design

PS Champagne Flutes Injection Mold, Complex Mold Design Custom Mold for PS+PS Water Jug, Two-shot molds

Custom Mold for PS+PS Water Jug, Two-shot molds PS Material Spoon Injection Mould

PS Material Spoon Injection Mould Injection Molding for Polypropylene Storage Boxes

Injection Molding for Polypropylene Storage Boxes Injection Molding for HDPE Crates

Injection Molding for HDPE Crates- PC Juicer Injection Mold

- Heavy Duty Molds for Making PP Chair