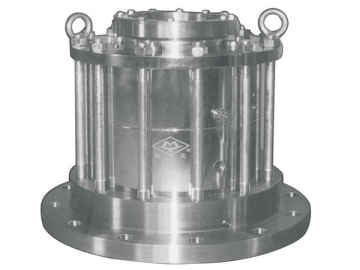

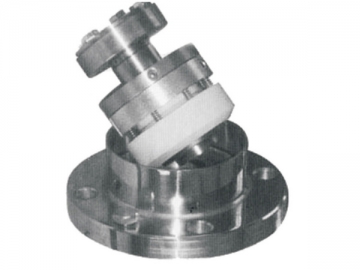

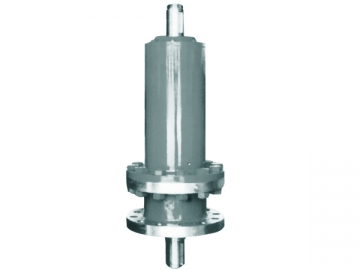

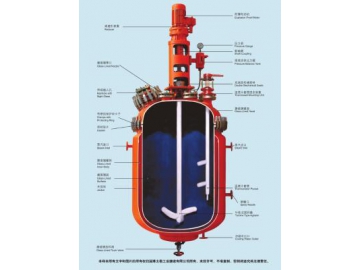

Reactor Using Mechanical Seal

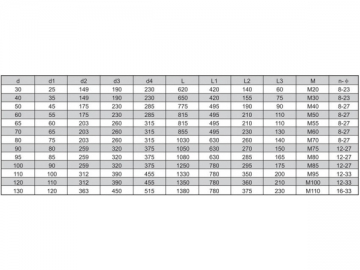

- Dry Milling Type Mechanical Seal

- FMY212 Mechanical Seal

- ZT212 Mechanical Seal

- FMY204 Mechanical Seal

- Type 205/206/207 Mechanical Seal

- Type 2001/2002/2004/2005 Mechanical Seal

- Type 2009/2010/2011/2012

Mechanical Seal - Metal Bellows Mechanical Seal

| Type | Dry Milling Type | FMY212 | ZT212 | FMY204 | Type 205/206/207 | Type 2001/2002/ 2004/2005 | Type 2009/2010/ 2011/2012 | Metal Bellows Mechanical Seal |

| Pressure | <0.5MPa | 0-0.8MPa | 0-0.4MPa | 0.1-0.6MPa | 205: 0.1-0.6Mpa, 206: 0.1-1.6MPa, 207: 0.1-2.5MPa | 2001, 2002: 0.1-0.6Mpa; 2004, 2005: 0.1-1.6MPa | 0.1-1.6MPa | Type2013,2014: 0.1-1.0MPa; Type2015,2016: 0.1-2.5MPa |

| Temperature | <120℃ | -40~180℃ | -20~120℃ | -40~180℃ (350℃ ) A cooling water tank is required to be set when the temperature exceeds 180℃. The mounting height, L2 and L3, is heightened by 80mm. | -20~180℃ (350℃) When the temperature exceeds 180℃, a high water tank is required to set and the mounting height, L1, is heightened by 80mm. | -40~180℃ (350℃) When the temperature exceeds 180℃, a high water tank is required to set and the mounting height, L1 or L2, is heightened by 60mm. | Type2013,2014 -40-450℃; Type2015,2016 40-450℃ | |

| Rotate speed | 300RPM | <2m/s | <2m/s | <2m/s | <2m/s | <2m/s | <2m/s | <2m/s |

| Medium | Various strong corrosive media except hydrofluoric acid and crystalline media | Various strong corrosive media or crystalline media | Acid, alkali, oil, polymer suspension | 205, 206: Oil, water, weak base, weak acid and other general media; 206, 207: Oil, water, weak base, weak acid, flammable, explosive, toxic gases, etc. | 2001, 2002: Oil, water, weak base, weak acid and other general media; 2004, 2005: Oil, water, weak base, weak acid, flammable, explosive, toxic gases, etc. | Various solvents, acids, alkalis, oils, polymer suspension | ||

| Structural feature | With a stationery design, the MY212 product can rotate at a speed as high as 10m/s when applied to steel reactor. | This type of product is applicable to steel reactors. | The product has an assembled structure and the components have strong university. The transmission is non-directional. It is mainly used for the shaft seal of enamel reactor and it can be applicable to various strong corrosive media with particles. It is usually used to support the use of hydraulic pump station. | |||||

| Remark | When the working pressure is greater than 0.6MPa, a pressure balancing device is required. | |||||||

The Reactor Using Mechanical Seal are ideal for the sealing of stirring shaft. According to the number of pairs of the sealing surface, they are divided into the two kinds of single end surface and double end surface. Our company provides multiple types of the product. The 205, 206 or 207 type of product is double-end and multi-spring. It reaches the purpose of sealing through the pressure difference between the sealing liquid inside the sealing chamber and the medium to be sealed. It can be used for the sealing of flammable, explosive and toxic gases or for situations which have strict sealing requirements.

Our Reactor Using Mechanical Seal adopt appropriate rotating and stationery rings materials as well as clean lubricating media, which can reduce the load factor of the end face and prevent heat distortion of the product, thus avoiding abrasion of the end face and increasing the service life of the product.

We are a China-based Reactor Using Mechanical Seal manufacturer and supplier. We also provide high temperature & high pressure mechanical seal, reactor, jet mill system, sand mill, bead mill system, and much more.

Related Names

Mechanical Sealing Part | Machinery Seal | Cartex Seal