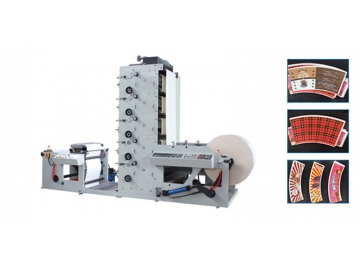

Paper Cup Flexo Printing Machine

Request a Quote

This flexo printing machine is designed for printing blanks of paper cups, it can automatically accomplish unwinding, web guiding, corona treatment, printing, drying and rewinding.

Technical Specifications

| Max. unwinding diameter | 1200mm |

| Printing repeat | 250mm-580mm (79T – 182T) |

| Max. printing width | 950mm |

| Power supply | 380V 3PH 50Hz |

| Total power | 30kW |

| Machine speed | 0-80m/min |

| Printing plate thickness | 1.7mm |

| Double sided adhesive tape thickness | 0.38mm |

| Printing precision | ±0.15mm |

| Air shaft diameter | 3inches |

Features

Unwinding unit and rewinding unit

- Automatic loading and unloading by hydraulic system

- Magnetic powder brake, motor used as clutch

Auto web guiding

- Splicing table

- Detection mode: edge checking

- Precision: ±0.1mm

Feeding system

- Rubber rollers for feeding

Printing unit (4 units)

- Helical gear

- Ceramic anilox roller: one set (4pcs)

- Printing roller: one set (4pcs)

- Ceramic anilox roller: LPI depends on buyer

- Printing roller: repeat depends on buyer

- Single side doctor blade

- Ink case

- Gear: cp1/8

Drying system

- IR drying

Auto stopping function

Meter counter

Simple plate mounter

Configurations

| Ceramic anilox roller | 1 set: 4 pcs, lines from 200-1000 choose by buyer | Murata, Shanghai |

| Printing roller | 1 set: 4 pcs | |

| Unwinding tension control | ZXTEC, Ruian | |

| Magnetic powder brake | Chinese brand | |

| Motor as clutch on rewinder | Lichao, Shanghai | |

| Rewinding converter | Zhengxian, Shenzhen | |

| Temperature control | XMTG-6501 | Yuyao , Zhejiang |

| Main motor | Lichao, Shanghai | |

| Main motor converter | YASKAWA, Japan | |

| Button | Schneider, France | |

| All low-tension electrical | CHINT, Wenzhou | |

| Web guiding | 1 | ZXTEC, Rui’an |

Details

Using efficient hydraulic system, each work station is 15-20 minutes faster than conventional machines;

Automatic tension control system on unwinding and rewinding unit

Auto web guiding system with splicing table

Printing unit with ink roller, ceramic anilox roller, printing roller, and impression cylinder

Main control panel with temperature control, meter counter and speed control

Rewinding unit with separate motor 7.5kW and separate inverter as clutch

Electric system

Cleaning mode when job is done