Industrial Injection Molding Solution

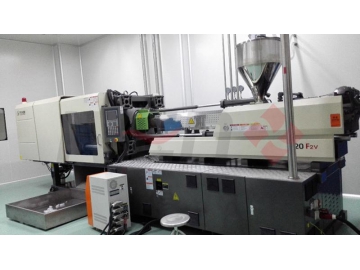

AERO MOLD is a professional supplier of plastic injection molds, with a focus on the design and production of a variety of plastic pipes, tubing coupling and other industrial plastic injection molds. Simply tell us your requirements, or send us your design drawings, and our mold designers, backed by extensive experience, will carry out die sinking in a short period of time. This same experience also allows us to focus on the mold precision and service life, thus ensuring a high quality mold service for our customers.

Sample PVC Pipe Elbow

PVC Pipe Elbow PP-R Pipe fittings

PP-R Pipe fittings PPR Pipe Reducer

PPR Pipe Reducer Plastic Connect

Plastic Connect Plastic Injection Molds for Cable Accessories

Plastic Injection Molds for Cable Accessories

Within a pipe system, the pipe fittings carry out connection, control, water diversion, water distributing, seal and support functions. Compared to traditional metal pipes and fittings, these plastic fittings are known for their light weight, corrosion resistance, high pressure resistance, hygiene and security, small flow resistance, energy saving performance, long lifespan and easy installation. Here at Aero Mold, we offer a variety of standard and non-standard plastic injection molds for pipe fittings.

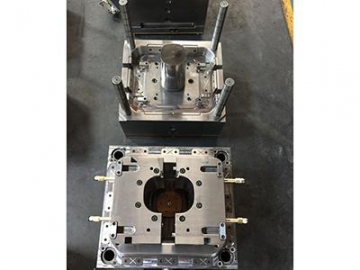

Materials used injection mold for pipe fittings- Mold base: Plastic mold steels of P20 and 2316 are used for the production of thin wall packaging molds, which avoids mold corrosion and water leaking through any loose connections.

- Mold core, mold cavity: Heat treated 2344 steel, S136 steel and other steels will undergo heat treatment to obtain a hardness of HRC 48-52. This design ensures a long mold life, and helps decrease the risk of mold rusting.

- Insert: Some inserts, such as the heated nozzle, are made using a heat treated S136 or 2083 steel. Not only that, but an insert installed on the top of the male mold's core uses BeCu (Beryllium Copper) instead of other materials, as BeCu is able to withstand the higher temperatures and poor heat dissipation found when inserts are located extremely close to the heated nozzle.

- If required, AERO MOLD can also manufacture thin wall packaging molds made of other materials.

PVC 90 Degree Elbow Mould, Cold Runner Mold

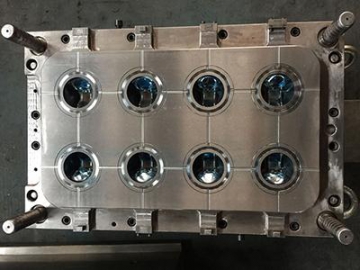

PVC 90 Degree Elbow Mould, Cold Runner Mold Double Shot, Hot Runner Mold for PPR Pipe Fittings

Double Shot, Hot Runner Mold for PPR Pipe Fittings Plastic Injection Molds for PA Material Cable Accessories

Plastic Injection Molds for PA Material Cable Accessories