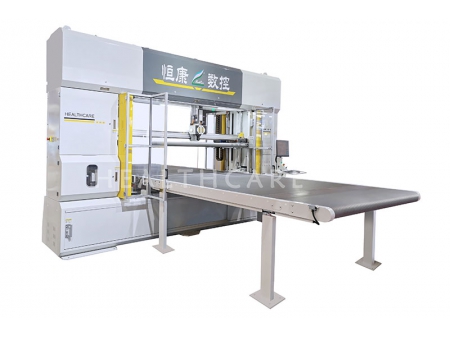

Vertical Continuous Blade Contour Cutting Machine, CNCHK-9.1

CNC Foam Cutting Machine with High Efficiency

The vertical blade foam contour cutting machine features automated foam cutting CNC technology, resulting in various advantages for foam fabrication including improved dimensional accuracy, increased cutting speed, consistency of contoured parts, reduced foam dust. This foam cutting machine can be connected with lifting table and automatic splitting machine to create a cutting line, ensuring reduced time for foam loading and unloading operations. This significantly improves working efficiency. This CNC foam machine is suitable for use in the foam fabrication which frequently requires vertical contour cutting in a continuous manner.

The vertical blade foam contour cutting machine features automated foam cutting CNC technology, resulting in various advantages for foam fabrication including improved dimensional accuracy, increased cutting speed, consistency of contoured parts, reduced foam dust. This foam cutting machine can be connected with lifting table and automatic splitting machine to create a cutting line, ensuring reduced time for foam loading and unloading operations. This significantly improves working efficiency. This CNC foam machine is suitable for use in the foam fabrication which frequently requires vertical contour cutting in a continuous manner.

- Foam sheet

- Coated materials

- Coated materials

- Foam fabrication

- Upholstered furniture

- Packaging

- Automotive

- Household

- Cellulose sponge

- EPE foam

- Polyester wadding

- Composite foam

- Polyester fiber

| Max. block size | 3000*2300mm |

| Cutting height | 1000mm, 1200mm |

| Blade size | 14770*3.5*0.6mm, 15150*3.5*0.6mm |

| Torsion range of blade | ±360° |

| Grinding device | Yes |

| Cutting speed | 0-60m/min |

| Accuracy | ±1mm |

| Press roller | Option |

| Baffle | Option |

| Lifting table | Option |

- High cutting speed up to 60m/min

- Few wear parts

- Simple operation with state-of-the art control technology

- CNC contour knives with long service life

- High level of automation: automatic foam feeding, automatic knife adjustment, etc.

- Dust-free cutting: Foam is cleanly sliced, not abrasively cut, so there is no dust generated. A clean dust-free surface to the finished product is essential for mattresses, pillows and medical applications. This also helps keep a clean, safe workplace.

- The foam processing which is interrupted due to power outage will start from the breaking point after power on.

- Absolute value of system, stable and reliable.

- Knife guide improves the cutting accuracy

- ZWCAD (available with commonly used keyboard shortcuts, automatic typesetting, one button for creating cutting path)

- 5 Band knife running wheels

- Electric cables with superior resistance to bending and twisting

- With automatically sharpening device, it can also improve the cutting accuracy.

- Lower knife twisting device designed with blowing function for cleaning and cooling the band knife

- Side holding device(manual or automatic)

- Baffle on the left and right (automatic)

- Compression unit with press roller and press plate

- Lifting table for loading and unloading

- Extension table

- Nesting software

- Can upgrade to cutting line by adding horizontal slicing machine.