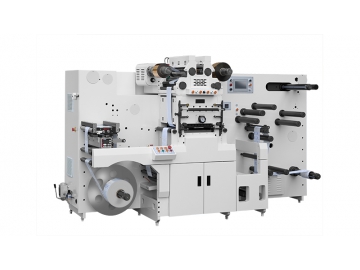

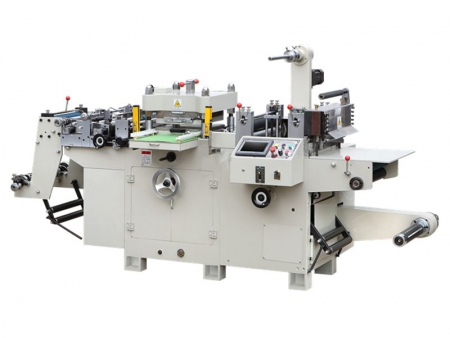

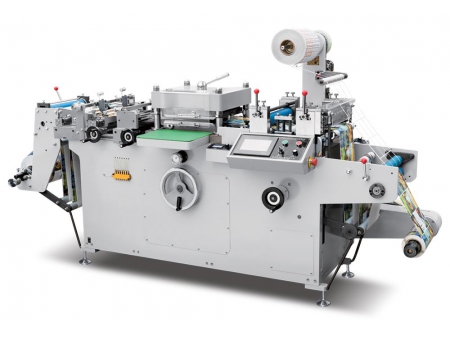

KISS-SD330 High Speed Flat Bed Die Cutting Machine

Request a Quote

This product has been discontinued and removed from our shelves.

The flat bed die cutting machine can offer an exceptionally efficient solution by using patented technology. It is outfitted with a special dancer system, which enables the paper to be fed at an unprecedented speed of up to 120 meters per minute. In addition, this high speed cutting machine is designed with multiple modules, including: rotary flexo printer, cold foil, flatbed hot foil, hot laminator, sheeter, slitter, and so forth.

Technical Parameters of the KISS-SD330 Die Cutting Machine

| Max. Die Cut Speed | 400cycle/min. (About 120m/min.) |

| Accuracy of Adhesive Cutting | ±0.15mm |

| Max. Die Cutting Area | 310mm×320mm (L×W) |

| Paper Width | 100-330mm |

| Max. Unwinding Dia. | ø700mm (≈2000meters) |

| Max. Rewinding Dia. | ø700mm (≈2000meters) |

| Repeat Length of Die Cutting | 50mm~310mm |

| Motor Power | 11kw |

| Overall Diameter (L×W×H) | 2600mm×1200mm×1500mm |

| Weight | 3000KGS |

| Power Supply | AV, 380V, 50HZ, 3 phases, 4 wires |

| Air Supply | 100p.s.i |

- Unwinder

1. Closed-loop tension control

2. Machine stops or decelerates when less paper is fed.

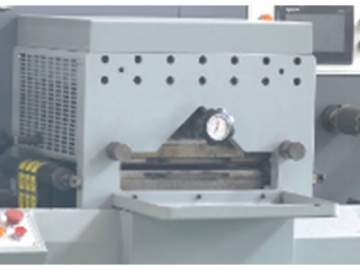

3. Automatically controlled web guider with ultrasonic system - Flatbed Die Cutter

Independent servo driver operates with mark sensor to guarantee high speed and stable operation.

- Flexo Printer

1. Available with a choice of semi-rotary or full rotary mode

2. Ideally suited for coating or foil

3. Hot air dryer option - Rewinder

1. Closed-loop tension control system works with powder clutch to ensure continuous stable tension

2. The motor slows down as the number of rolls increases.

- Laminator

1. Powder tension control system

2. Movable unwinder

3. Optional liner rewinder - Slitter

shear slitter or razor slitter

- Sheeter

1. Independent servo drive

2. Easy set-up function

3. Optional auto collection system - Hot Laminator

1. Huge size heating roller

2. Stable temperature control

Related Manufacturies

Leave Message

Similar Manufacturies and Parts

Manufacturer Advertising

More

Similar Manufacturies and Parts

Videos