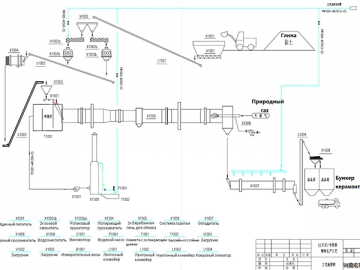

Compound Fertilizer Production Line

Compound fertilizer production line involves many procedures such as measurement, crushing, pelleting, drying, cooling, screening, coating and packing. The procedures can be customized according to customers’ requirements.

Blending

Operators should add nitrogen, phosphorus, potassium and other additives into the electronic belt scale in strict accordance with technical personnel’s requirements for quantity of each kind of raw material. The raw materials need to be in form of powder or granularity if no lump exists. It is required to continuously add the raw materials because interval material flow will decrease measuring accuracy and interfere pelleting process, which seriously deteriorates quality of finished product. After measurement and blending, the raw materials will be delivered to the crusher.

Crushing

Raw materials enter the crusher through the feed inlet. Then the high speed rotor driven by the motor smashes the materials into small particles with desired size. The crusher also accomplishes secondary blending. Then these small particles enter the belt conveyor through the discharge outlet and then enter the rotary drum granulator for pelleting.

Pelleting

In the rotary drum granulator, rotation of the shell will move the particles upward, while gravity will draw the particles downward. Hence, the particles will make reciprocating movement, thus ensuring large contact area. Meanwhile, a certain proportion of adhesive will be added into the drum to glue the particles together. The particles wrap around the granulation nucleus layer by layer and gradually turn into pellets, which will be delivered to drying process.

Drying

The dryer shell is assembled using flanges and it is edge-driven. The dryer achieves direct-contact heat transfer, so that it is suitable for drying granular compound fertilizer. In addition, a pelleting section is installed in the interior of the dryer for secondary pelleting of loose particles. As a result, granulation rate of the whole production line is enhanced greatly. When drying process finishes, the fertilizer will be delivered by the belt conveyor to the cooling system.

Cooling

Rotary cooler is primarily applied to quickly decrease the temperature of the compound fertilizer to room temperature after drying process, which facilities packing of the fertilizer and prevents lumping in storage. Then the belt conveyor will bring the cooled materials to next procedure.

Screening and Crushing of Large Particles

Generally, semi-finished product consists of fine powder, finished product and large particles. Screen is used to separate them from each other. First, fine powder will be easily separated. Then large particles are sorted out and then be delivered to the crusher for further size reduction. Later, both fine powder and large particles return to the pelletizer through belt conveyor for further pelleting. The finished product will be transported to next process.

Packing

Finished product is delivered to the storage silo on the packing machine through the belt conveyor. Then the product will be unloaded by a preset constant weight on the scale for automatic weighing, and then be packed and sealed.

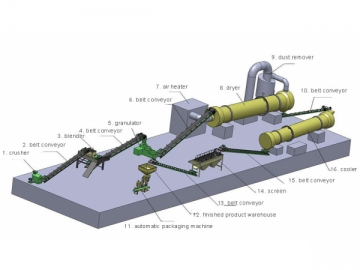

1. crusher

2. belt conveyor

3. blender

4. belt conveyor

5. granulator

6. belt conveyor

7. air heater

8. dryer

9. dust remover

10. belt conveyor

11. automatic packaging machine

12. finished product warehouse

13. belt conveyor

14. screen

15. belt conveyor

16. cooler