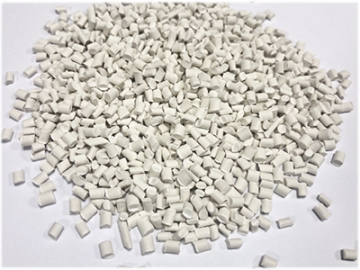

Red Phosphorus Flame Retardant Powder

Red-P FRP is refined through scientific formula with new coating technology and polymer materials as coating material. Through coating, the activity of red phosphorus is reduced, and the compatibility and fluidity are improved. While maintaining the red phosphorus's flame retardancy and enhancing its temperature resistance, we also solved the problem of moisture absorption of red phosphorus. Therefore, it has been widely used in polymer materials.

| Item | Unit | Value |

| The contend of red phosphorus | 50% to 85% The content can also be customized according to customer requirements | |

| Appearance | Dark brick red powder | |

| Feature | Superfine coated | |

| Density | g/cm3 | 1.4 to 1.6 |

| Content of water | % | ≤0.5 |

| Particle size | μm | 8 to 15 |

| Ignition temperature | ℃ | ≥300 |

| Melting temperature | ℃ | ≥360 |

| Properties | UL94-V0 (T2.0 mm) | |

- High efficiency with small addition.

- Good thermal stability, no decomposition at about 300 ℃;

- Good compatibility with polymers and good mechanical property.

- Eco-friendly, non-halogenated, achieve SGS and RoHS requirements.

- It can be used alone or combined with other flame retardants and additives.

Red phosphorus flame retardant powder can be used for producing PE, PP, EVA, PET, PBT, PA, PC and other thermoplastic resins. It can also be used for flame retardation of thermosetting resins such as epoxy, phenolic and unsaturated polyester. If it is used for flame retardation of general plastics, rubber, polyethylene, polypropylene and other materials lacking oxygen, the effect of compounding with magnesium hydroxide and aluminum hydroxide is better.