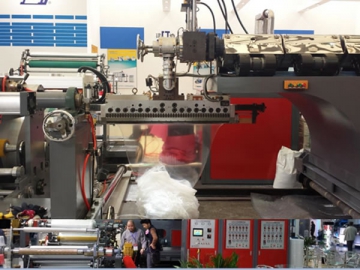

Double Side Extrusion Lamination Machine

This double side extrusion laminating machine works with PE or PP coating resin, it can laminate with following base rolls, like BOPP film, PET film, aluminum foil, non-woven fabrics, paper, etc. The finished product is PE + BOPP film, PE + PET film, PE aluminum foil, PE non-woven fabric, PE paper, which is widely used in composite flexible packaging field like medicine packing, food packing, office tools packing, architecture packaging, and so on.

Features- The three-roller film laminating machine is equipped with adjustable die head. Auto-load feeder is working with drying system. The plastic extruder adopts frequency motor to adjust speed.

- Screw heating part adopts auto-temperature control system, and is heated by air-cooled ceramic heater.

- The lamination roller adopts double inside water cooling system which can ensure the lamination film with good quality and long-term high speed operation.

- First feeding station adopts frequency motor for automatic tension control unwinding, and automatic edge position control system.

- Second feeding station adopts magnetic powder brake, and double-station turret-type exchanging device.

- Double side corona treatment is adopted to make sure the lamination quality.

- Trim cutting device uses negative pressure fan, it can storage the materials after crushing.

- Rewinding and unwinding machine has the functions of auto-tension adjustment and auto meter counting, so that it enables high speed stable running and high laminating quality.

- This extrusion laminating machine is PLC controlled, it has the characteristics of full automatic operation, high speed, even laminating surface, high degree of adhesion, level winding, etc.

- It is a new designed laminating machine with more advanced technology. Compared with traditional lamination machine, the glue coating system and oven heating system are not required. Our double side extrusion laminating machine can simplify the whole structure and production process, reduce the energy consumption, it is easy to operate, and environmental friendly.

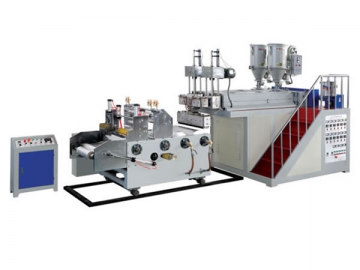

| Model | JDGLM-1000 |

| Main Screw Diameter | 100mm |

| Minor Screw Diameter | 70mm |

| L/D | 33:1 |

| Product Width | 1000mm |

| Lamination Thickness | 0.01-0.1mm |

| Max. Line Speed | 180m /min |

| Output | 300kg /h |

| Main Motor Power | 55kw |

| Minor Motor Power | 30kw |

| Total Power | 175kw |

| Weight | 15t |

| Overall Dimension(L×W×H)mm | 10m ×90m×3.6m |

| Power Supply | 380/3/4 /50(Volt/Ph/Line/Hz) |

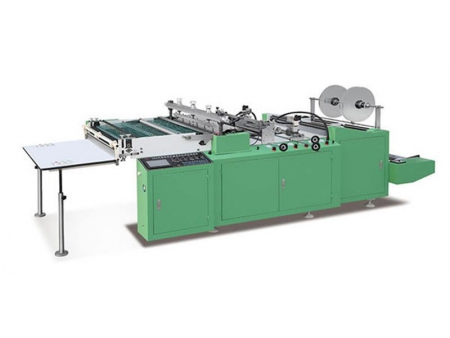

Related products

Send Message

Most Recent

More

Other Products

Videos