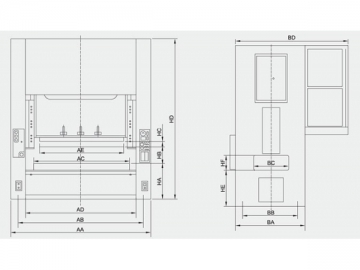

Single Crank Press (200-600 Tons), STS Series

High Precision Press | Sheet Metal Forming | 200 - 600 Metric Tons Capacity

Our STS series single crank press is a high precision press machine that features a box-type center position slider that has a wide guide path. This effectively eliminates the natural deformation to the work piece caused by the high-torque punch. This power press is especially suitable for high precision punching and thick metal sheet forming. Yiduan is an automotive stamping company in China and we can provide custom stamping presses in addition to our standard line of products.

1. Advanced European, American and Japanese technologies/functional structure including a CAE dynamic simulation optimized design

2. High-standard metalworking process of such key parts as gears and axles through hard chrome plating/nitriding/grinding

3. High-standard fabrication processing of such key parts as gears and axles through hard chrome plating/nitriding/grinding

4. High-level configurations of high-performance controllers/drive parts/electromagnetic clutches/steam-driven elements and bearings

5. Technical grade international sheet meal forming machine and inspection of machine index

6. High-response multi-functional superposition expansion/high-quality industrial control processor

7. High-memory module/individual design franchised software compilation

8. High-compatibility multi-axial variable speed drive/ onboard automation equipment expansion

9. Intelligent interface/high frequency real-time control/Ethernet & USB interface configuration

1.Oil pressure overload protection device

2.Electric slide adjust device

3.Die height indicator (unit: 0.1 mm)

4.Slider and mold balancing device

5.Rotary cam switch

6.Crank angle indicator

7.Circulation centralization lubrication device

8.Electromagnetic stroke counter

9.Over-run safety device

10.Programmable controller

11.Mobile T-type operating floor

12.Air source connector

13.Independent electric control cabinet

14.Maintenance tool and tool box

1.Die cushion

2.Upper slide feeding device

3.Die Light

4.Main motor inversion device

5.Photo-electric safety device

6.Safety groove and safety plug

7.Preset counter (6 digits)

8.Loading inspection device

9.Misfeed detection device

10.Frequency converter

11.Basic bolt and soleplate

12.Anti-vibration foot

13.Safety shelf and safety ladder

14.Power socket

15.Quick die change device