Door Frame Roll Forming Machine

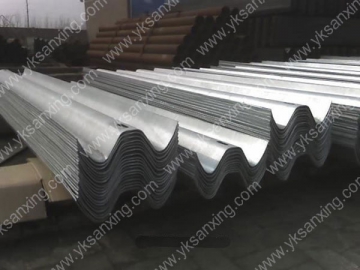

Application of Door Frame Roll Forming Machine

Steel door frame machines are a great choice for strength and durability, resulting in a finished product of the highest quality and great strength, offering a high level of security. The door frame roll forming machine is essential for the production of steel door frames.

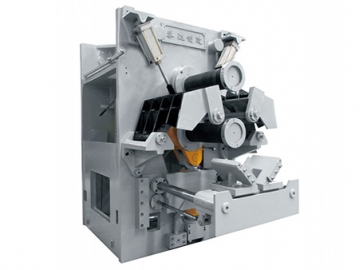

Work Flow of Door Frame Roll Forming Machine

Decoiling ---> Feeding Guide ---> Roll Forming ---> Hydraulic Cutting ---> End

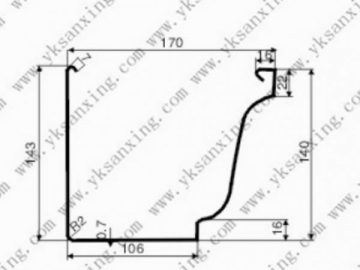

Technical Parameter of Door Frame Roll Forming Machine

A. Manual Decoiler

B. Roll Forming M/C

(1) Raw Material: Colored steel or galvanized steel

(2) Material Thickness: 1.0-1.5mm

(3) Working Speed: 8-12m/min; Adjustable

(4) Rollers: 14 rollers (based on profile)

(5) Material for Rollers: GCr15, polished, heated, quenched HRC55-60°

(6) Motor Power: 11 KW

(7) Roller Diameter: 76mm

(8)Transmission Type: Chain Transmission

(10) Appearance Size: About 10,000mm x 1300mm x 1200mm

(11) Total Weight: About 8T

C. Hydraulic Cutting

(1) Cutting Type: Hydraulic, automatic cutting

(2) Blade Material: Cr12 with polished, heated, quenched HRC 60-62

(3) Power: 3KW

D. Control System

(1) Electrical Control: PLC Frequency Control System with touch screen

(2) Voltage: 380V/3Ph/50Hz (or as your local standard)

(3) Length Error: ±1mm