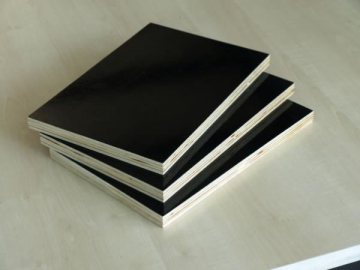

Film Faced Plywood

Description

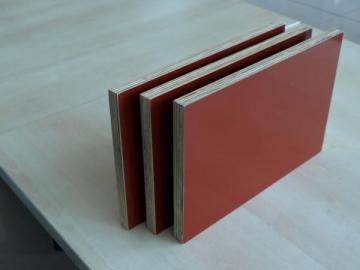

Film faced plywood is lightweight, and resistant to corrosion and water. It is easily combined with other materials to make it easy and clean to cut. Treating the film faced plywood’s edges with a water proof paint also makes it incredibly water and wear resistant. Due to the durability, it can be used in open environment applications, such as warehouses, railway wagons, floors, and sidewalls in trucks. Coating the film faced plywood with high quality, imported films ensures the hardness and damage resistance. The surface of this plywood is hygienic and resistant to chemicals in strong detergents, making it great for use in farming and food storage. It can be used in areas of great temperature fluctuations, moisture saturated areas, and more, while it also provides protection from termites.

We offer two types of film faced plywood:

1. Birch film faced plywood is resistant to water, and is easy to clean and cut. It is among the highest quality plywood types in the world.

2. Poplar film faced plywood is also easy to clean and cut. It is softer and lighter than birch film plywood.

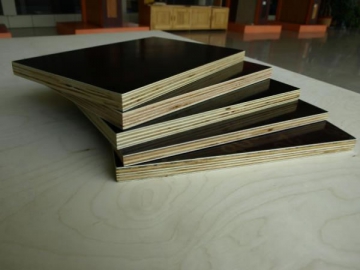

Phenolic film utilizes advanced technology, givng the template a smooth surface, high strength, light weight, water resistance, corrosion resistance, warp prevention, and cracking prevention. This plywood can be used multiple times, reducing costs and is applicable to multiple types of construction projects.

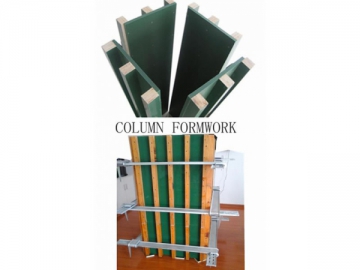

Applications

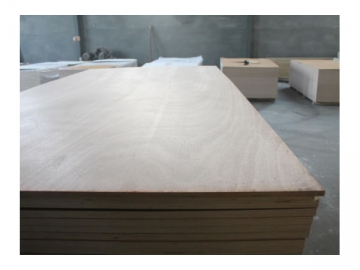

Due to its durability, film faced plywood is widely used in construction, building and vehicles for making transportation equipment containers, loading platforms, truck and trailer floors and wagons. This material is also used to make tables, chairs, sofas, beds, sliding doors, advertising boards, playground equipment, sports arena flooring, smooth concrete casts, scaffolding, fencings and more.

Features:

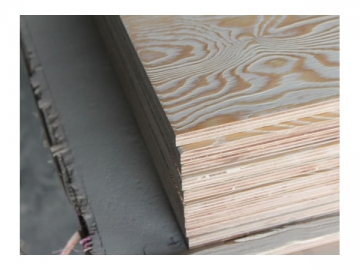

1. Made of plywood, light weight, easy handling.

2. Grooves prevent the leakage of concrete

3. Easy cutting

4. Efficient installation and dismantling

5. Nice concrete finish without re-work

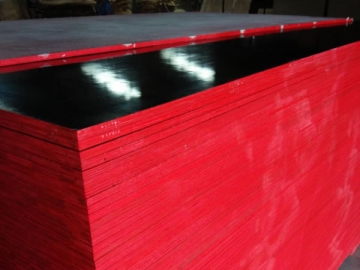

Product Name: Film faced plywood

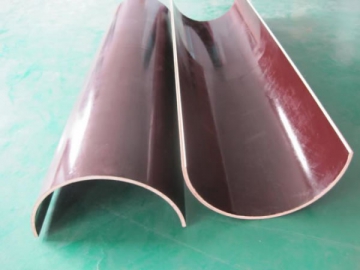

F/B: Black film, brown film, red film

Grade: Construction grade (one/two time hot press)

Core: Poplar, hardwood, birch, pine, combo and so on

Glue: Mealmine and WBP

Thickness: 9-25mm

Specification: 1220x2440mm, 1250x2500mm, 915x1830mm

Moisture Content: 8-10%

Package: Standard export packing

Press: One times press/two time press grade

Supply Capacity: 4500 cbm/month

Usages: Can be widely used for building concrete,

Remarks: Top class equipment with top class produce technique, credit first, fair trading

Other search items: film faced birch plywood, film faced poplar plywood