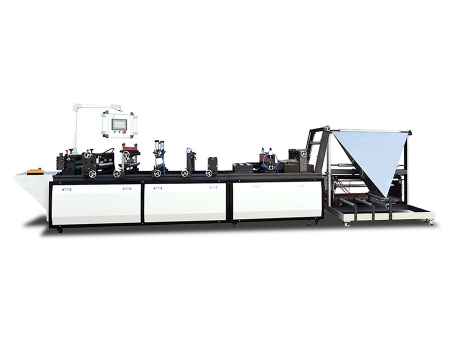

SZB1050S Carrier Bag Making Machine

The SZB1050S carrier bag making machine utilizes single piece of paper, handle fixing roll paper, and paper string as raw material. The paper bag making machinery is capable of completing handle making, handle sticking, bag rim folding, bag body forming, accordion folding, bottom sealing, and compaction. It also supports the procedures of handle fixing paper sticking, bag rim folding, bag body forming, accordion folding, hole punching, bottom sealing, and compaction.

The multiple functions of the carrier bag making machine makes this product suitable for manufacturing paper bag for garment, shoes, and the external hand bag for luxury. The full automation is conducive to the high productivity of the carrier bag forming equipment.

Technical Parameters of Carrier Bag Making Machine| Applicable Paper | Kraft paper, art paper (including PE coated paper) |

| Max. Paper Size | 1000×550mm |

| Min. Paper Size | 540×350mm |

| Paper Gram Weight | 90g-190g/m2 |

| Height of Accordion Folding | 80-150mm |

| With of Paper Bag | 180-340mm |

| Handle Length | 180mm |

| Handle Width | 45mm |

| Handle Spacing | 90mm |

| Total Power | 15kW |

| Overall Dimensions (L×W×H) | 16.1×5.1×3.1m |

| Production Capacity | 45-55 bags/min |

| Machine Weight | 16 tons |

| Glue | Water-soluble cold melt glue (Hot melt glue) |

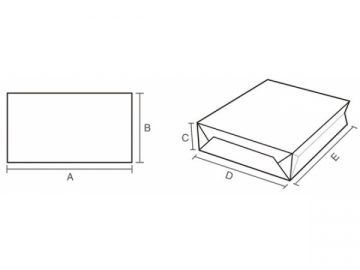

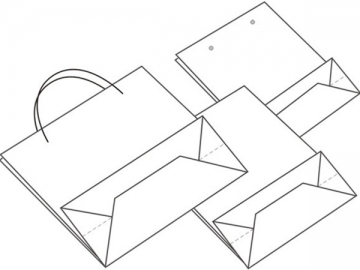

| Item | A | B | C | D | E |

| Max. Size | 1000 | 550 | 150 | 340 | 490/435 |

| Min. Size | 540 | 350 | 80 | 180 | 250 |

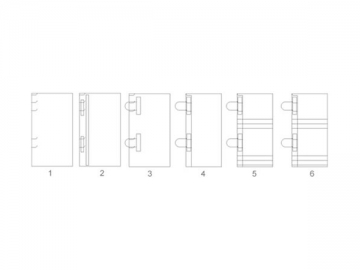

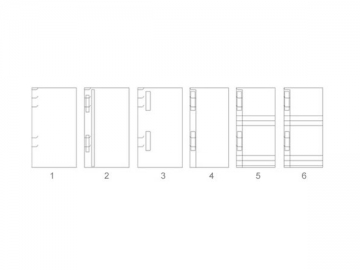

- 1. Cutting

- 2. Gelatinizing

- 3. Handle fixing

- 4 .Bag rim folding

- 5. Accordion line marking 6. Gelatinizing

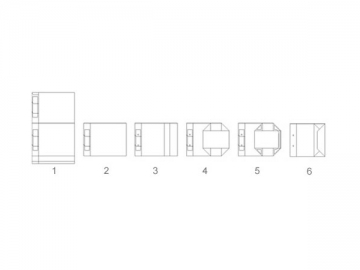

- 1. Accordion folding

- 2. Bag body folding

- 3 .Bottom folding line pressing

- 4. Bottom forming

- 5 .Gelatinizing

- 6. Bottom sealing

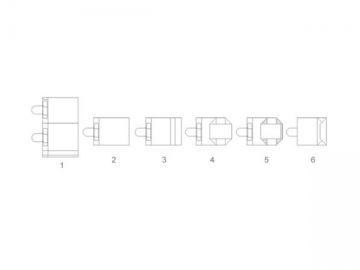

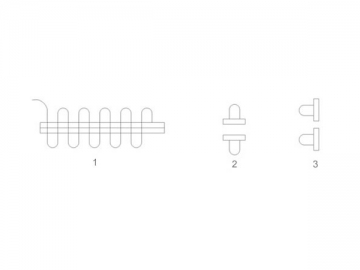

- 1. Handle making

- 2. Handle cutting

- 3.Handle positioning

- 1. Cutting

- 2. Gelatinizing

- 3. Handle fixing

- 4. Bag rim folding

- 5. Accordion line marking

- 6. Gelatinizing

- 1. Accordion folding

- 2. Bag body folding

- 3. Bottom folding line pressing

- 4. Bottom forming

- 5. Gelatinizing

- 6. Bottom sealing

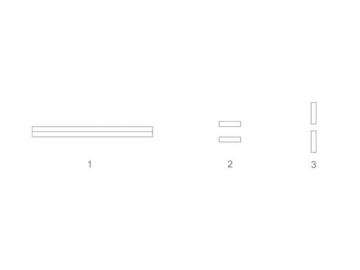

- 1. Handle fixer placing

- 2. Handle fixer cutting

- 3. Handle fixer positioning

Related products

Send Message

Most Recent

More

Other Products

Videos