Trailer Geological Core Drilling Rig

Judging from the name, trailer geological core drilling rig is fixed to a trailer that comes with radial tires. It is primarily applied to diamond drilling and carbide drilling on solid bed as well as base drilling, exploring drilling and pile hole drilling. Torque transfer of trailer geological core drilling rig is completed neatly due to its perfect configuration like light and compact mechanical transmission, octagonal structure spindle with a large diameter, long supporting span, good hexagonal pipe, etc. Meanwhile, hydraulic system is well adopted in trailer geological core drilling rig, that is, four hydraulic supporting jacks will balance trailer geological core drilling rig to make it more stable before work. And during feeding process, hydraulic mechanism will be used to adjust feeding speed and pressure in order to meet various drilling requirements on different stratums. Even masts, composed of main mast and mast extension, are hydraulically controlled, which makes trailer geological core drilling rig feature improved working efficiency, simple operation and easy transportation.

Besides, compared with common core drilling rig, our trailer geological core drilling rig is also characterized by low costs, for heavy derrick has been removed. Moreover, high and optimum rotating speed enables the drilling rid to satisfy requirements of various drillings such as small diameter diamond drilling, large diameter carbide drilling and all kinds of engineering hole drillings. Other advantages of trailer geological core drilling rig are as follows: first, it comes with a bottom-hole pressure gauge to monitor drilling pressure. Second, centralized control panel ensures convenient operation of the trailer geological core drilling rig. Last, automobile type transmission and clutch make the drilling rig feature universality and easy maintenance.

| Fundamental parameters | ||||

| Unit | XYT-200 | XYT-2B | XYT-3B | |

| Drilling depth | m | 280 | 300 | 600 |

| Drilling diameter | mm | 60-380 | 80-520 | 75-800 |

| Rod diameter | mm | 50 | 50/60 | 50 60 |

| Drilling angle | ° | 0-90 | 70-90 | 70-90 |

| Overall dimension | mm | 4460x1890x2250 | 4460x1890x2250 | 5000x2200x2300 |

| Rig weight | kg | 3320 | 3320 | 4120 |

| Skid | ● | / | / | |

| Rotation unit | ||||

| Spindle speed | ||||

| Co-rotation | r/min | 88, 197, 296, 399, 655, 888, | 70,146,179,267,370,450,677,1145, | 75,135,160,280,355,495,615,1030, |

| Reverse rotation | r/min | 66, 147 | 70, 155 | 64,160 |

| Spindle stroke | mm | 510 | 550 | 550 |

| Spindle pulling force | KN | 49 | 68 | 68 |

| Spindle feeding force | KN | 29 | 46 | 46 |

| Maximum output torque | N.m | 1700 | 2550 | 3500 |

| Hoist | ||||

| Lifting speed | m/s | 0.31, 0.72, 1.06?? | 0.64,1.33, 2.44 | 0.31,0.62,1.18,2.0 |

| Lifting capacity | KN | 20 | 25, 15, 7.5 | 30 |

| Cable diameter | mm | 12 | 15 | 15 |

| Drum diameter | mm | 170 | 200 | 264 |

| Brake diameter | mm | 296 | 350 | 460 |

| Brake band width | mm | 60 | 74 | 90 |

| Frame moving device | ||||

| Frame moving stroke | mm | 420 | 420 | 420 |

| Distance away from hole | mm | 250 | 300 | 300 |

| Hydraulic oil pump | ||||

| Type | YBC12-125 (left) | CB-25 | CBW-E320 | |

| Rated flow | L/min | 18 | 40 | 40 |

| Rated pressure | Mpa | 10 | 8 | 8 |

| Rated rotation speed | r/min | 2500 | ||

| Power unit | ||||

| Diesel engine | ||||

| Type | L28 | N485Q | CZ4102 | |

| Rated power | KW | 20 | 24.6 | 35.3 |

| Rated speed | r/min | 2200 | 1800 | 2000 |

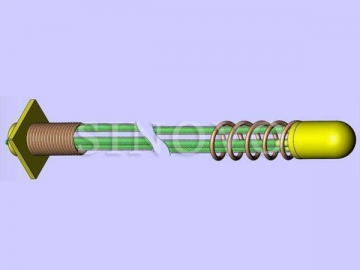

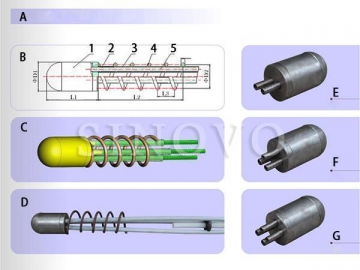

A. OQM-d Series Retrievable Anchorage Cable

B. Sectional View

1. Supporting Part

2. Connector

3. Plastic Pipe

4. Coil

5. Steel Strand

C. 3D Drawing

D. Product Photo

E. 2 holes

F. 3 holes

G. 4 holes