Chicken Seasoning Granulating Drying Machine

Chicken Seasoning Granulating Drying Machine

Chicken essence is verypopular in international market. Our chicken seasoning granulating dryingmachine is designed for producing high quality chicken essence with highsanitary standard and scientific production processes.

In order to meet customers’ different demands, we can offer chicken seasoning productionmachines with different specifications, thus allowing customers to constructchicken seasoning production lines with different production flows.

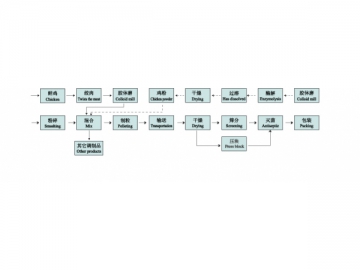

Process Flow Sheet

Recommendations

A great variety of machines areutilized for chicken essence production. Following are some recommended typesof chicken seasoning granulating machine and drying machine, etc. for use inchicken seasoning production.

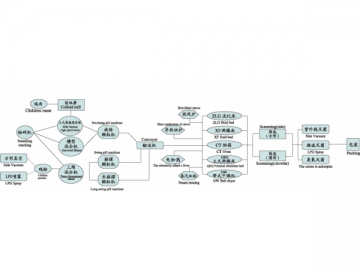

Chicken Essence Production Line

1. Small scaled chicken essence production line (

It is a small scale chicken seasoning production machine with a production capacityof

This chicken seasoning production line is easy for transportation andinstallation. It requires less investment and is ideal for individual users. Inorder to help users know well how to operate the chicken seasoning production line,we can offer technical training, technical support, and so on.

2. Belt dryer

Belt dryer is one of the commonly used chicken seasoning production machinesfor chicken essence production. Raw materials are distributed uniformly on thebelt and stay in static status during drying process. This makes sure there isa high qualification rate for the chicken essence granules.

The belt dryer is large in length, so it requires large space for installation.We recommend using belt dryer in combination with our YK-160 (200) × 1200(1600) type granulating machine, so as to reduce production steps and improveproduction efficiency during chicken essence production.

Patented Chicken Seasoning Production Machine

1. YK-160(200)×1200(1600) Swinggranulator

This granulator has long rollers and can finish granulation, grinding, andmaterial distribution functions. It has high production capacity and compactstructure.

This chicken seasoning granulating machine can be used in combination withdrying machine to create a chicken seasoning granulating drying machine.

2. ZL

The rotary granulator is directly connected with a motor reducer. It offers lowspeed output, high productivity and stable operation. During chicken seasoningproduction, it can be used for making chicken powder into granules.

3. ZGH-350 High speed mixer

The high speed mixer can be used for mixing dry powder, slightly-moistenedpowder, and small granulated materials. It can be used in combination withtraditional groove mixers for chicken seasoning production.

Advantages of Chicken Seasoning Production Equipment

1. Gas sealing technology for use in swing granulator

The swing granulator, one of our range of chicken seasoning machines, isdesigned with a compressed air groove for its shaft end seal. It takesadvantage of compressed air to prevent damage to shaft end seals, thus ensuringreliable sealing performance.

2. Nozzle is utilized in the mixers for ensuring uniform mixing.

CH mixer, a typical chicken seasoning production machine, is ideal for mixingsolid materials with liquid material. In order to ensure uniform mixing betweensolid and liquid materials, it is designed with nozzles to spray liquids ontosolid materials.

3. Easy dismantling structure for vibration fluidized bed dryer

The vibration fluidized bed dyer, also a kind of commonly used chicken seasoningproduction machine, is designed with an easy-dismantling structure. So it iseasy for cleaning, which ensures the sanitary standard during chicken seasoningproduction process.

We can design and manufacture chicken seasoning production machine according tocustomers’ demand, whether that is chicken seasoning granulating machine,chicken seasoning drying machine, or mixing machine.