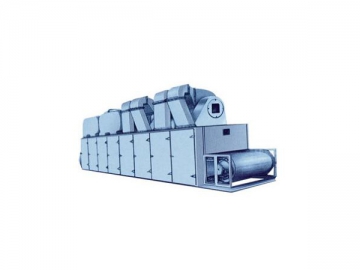

Belt Drying Equipment

BeltDrying Equipment

Descriptionsof the Belt Drying Equipment

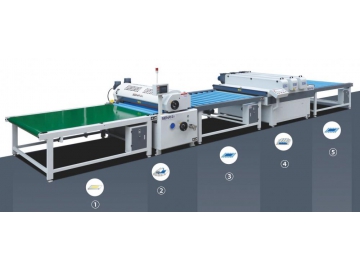

Raw materials to be treated must be evenly distributed onto aconveyer belt. This is accomplished through the use of a star distributor,swing belt, crusher, or granulator. The belt drying equipment conveyer passesthrough a channel with one or more heating units. Each heating unit is equippedwith an air heater and circulating system. Each channel has one or more dampdischarge systems. When the belt drying equipment conveyer passes through, hotair moves through the raw material from either above or below. In this way theraw materials are dried evenly.

Application

The Belt Drying Equipmentis popular for continuous drying. It is widely used in the chemical industry,foodstuff industry, pharmaceutical industry, construction materials industry,electronics industry, and more. This is exceptionally suited for drying rawmaterials that are shaped in strips or granules. It is alsopossible to dry raw materials that are paste, such as filter cake, after beingformed by a granulator or extruder.

Typical Products

Products the belt drying equipment is used for include dehydratedvegetables, granule feed, monosodium glutamate, check extraction, organicpigment, synthetic rubber, propylene fiber, medicine, medical materials, smallwooden products, plastic products, and more.

Technical Parameters of Belt Drying Equipment

| Type | DW-1.2-8A | DW-1.2-10A | DW-1.6-8A | DW-1.6-10A | DW-2.0-8A | DW-2.0-10A | |

| Qty of unit | 4 | 5 | 4 | 5 | 4 | 5 | |

| Length(m) | 8 | 10 | 8 | 10 | 8 | 10 | |

| Thickness of material(mm) | ≤60 | ||||||

| Using Temp( ℃ ) | 50-140 | ||||||

| Steam pressure(MPa ) | 0.2-0.8 | ||||||

| Steam consumption(kg/h) | 120-300 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | |

| Drying time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | |

| Drying strength (kg H2O/ m2h) | 6-30 | ||||||

| Power of engine(kW) | 11.4 | 13.6 | 11.4 | 13.6 | 12.5 | 14.7 | |

| Dim(m) | A | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 |

| A1 | 2.28 | 2.28 | 2.68 | 2.68 | 3.2 | 3.2 | |

| B | 8.0 | 10.0 | 8.0 | 10.0 | 8.0 | 10.0 | |

| B1 | 9.5 | 11.5 | 9.5 | 11.5 | 9.5 | 11.5 | |

| C | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Type | DW-1.2-8A | DW-1.2-10A | DW-1.6-8A | DW-1.6-10A | DW-2.0-8A | DW-2.0-10A | DW3-1.2-8B | DW3-1.2-10B | DW3-1.6-8B | DW3-1.6-10B | DW3-2.0-8B | DW3-2.0-10B | |

| Qty of unit | 4 | 5 | 4 | 5 | 4 | 5 | 8 | 10 | 8 | 10 | 8 | 10 | |

| Length(m) | 8 | 10 | 8 | 10 | 8 | 10 | 24 | 30 | 24 | 30 | 24 | 30 | |

| Thickness of material(mm) | ≤60 | ||||||||||||

| Using Temp( ℃ ) | 50-140 | ||||||||||||

| Steam pressure(MPa ) | 0.2-0.8 | ||||||||||||

| Steam consumption(kg/h) | 120-300 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 240-550 | 300-750 | 300-750 | 340-950 | 350-1000 | 400-1200 | |

| Drying time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | |

| Drying strength | 6 月 30 日 | ||||||||||||

| (kg H2O/ m2h) | |||||||||||||

| Power of engine(kW) | 11.4 | 13.6 | 11.4 | 13.6 | 12.5 | 14.7 | 21.7 | 26.1 | 21.7 | 27.2 | 29.2 | 35.2 | |

| Dim(m) | A | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 |

| A1 | 2.28 | 2.28 | 2.68 | 2.68 | 3.2 | 3.2 | 2.1 | 2.1 | 2.8 | 2.8 | 3.2 | 3.2 | |

| B | 8 | 10 | 8 | 10 | 8 | 10 | 8 | 10 | 8 | 10 | 8 | 10 | |

| B1 | 9.5 | 11.5 | 9.5 | 11.5 | 9.5 | 11.5 | 12.5 | 14.5 | 12.5 | 14.5 | 12.5 | 14.5 | |

| C | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.6 | 3.6 | |

The parameters given above are for reference only. The dryingpower is affected by many factors, such as the properties of the raw materialsand operation temperature.

Xianfeng is a professional belt drying equipment manufacturer in