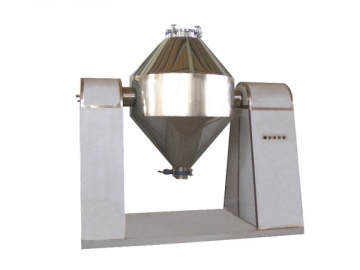

Revolving Vacuum Drying Equipment

RevolvingVacuum Drying Equipment

Operating Principles

The SZG Double Conical Revolving Vacuum Drying Equipment has adouble conical rotating cylinder. Under the state of vacuum in the cylinder,oil or hot water is passed into the jacket to heat. The heat comes into contactwith damp raw materials through the inner wall. The evaporated steam isexhausted through the vacuum pump. Because the inside of the cylinder of therevolving vacuum drying equipment is a vacuum and the cylinder makes the rawmaterial turn over from top to bottom and from inside to outside, the dryingspeed is speeded and the drying efficiency is raised, thus uniform drying canbe achieved.

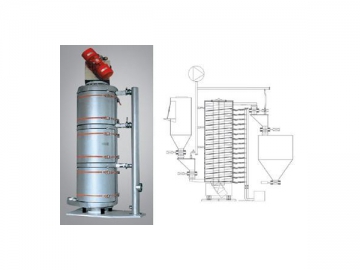

The Double ConicalRevolving Vacuum drying equipment is a new style dryer integrating mixing and dryingin one body. It is equipped with a condenser and vacuum pump. (If the solventdoes not recover, the condenser may not be used). The design of this machine isadvanced and its inner structure is simple. Therefore it is clean, veryconvenient, and the raw material can be discharged fully. It can reduce laborand improve the working environment. When the cylinder is rotating, the rawmaterial is rotated too, so it does not collect anywhere. Its coefficient of thermal transmission is high and thedrying speed is high. Not only does it save energy, but also the raw materialcan be dried fully and uniformly and the quality of the product is high. Therevolving vacuum drying equipment is used widely in the pharmaceuticalindustry, chemical industry, foodstuff industry, dyestuff industry, and more.

Scope of Application

The revolving vacuum drying equipment is suitable for vacuum mixing anddrying of powder and granular raw materials in the pharmaceutical industry,chemical industry, foodstuff industry, etc. Particularly it is suited for rawmaterials that have the following requirements:

1. Heat sensitive raw materials that cannot be dried at high temperatures.

2. Raw material that easily oxidizes or is dangerous.

3. Raw material that the solvent and toxic gases are needed to be recovered.

4. Raw material with special requirements for crystal shape.

5. Raw material that have special requirements for the content of volatileresiduals.

Technical Parameters of Revolving Vacuum Drying Equipment

| Model | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | |

| Volume inside the tank(L) | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | |

| Max Loading capacity(L) | 40 | 140 | 200 | 300 | 400 | 600 | 800 | 1400 | 1800 | 2000 | |

| Revolution (rpm) | 3-13 | 6 | 5 | 4 | 4 | 4 | |||||

| Power of motor(kW) | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | |

| Occupied area L×W | 2160*800 | 2160*800 | 2350*800 | 2560*1000 | 2860*1300 | 3060*1300 | 3260*1400 | 3760*1800 | 3960*2000 | 4400*2500 | |

| Rotating height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 | |

| Design pressure inside the tank(Mp) | -0.1-0.15 | ||||||||||

| Design pressure of jacket (Mpa ) | ≤0.3 Mpa | ||||||||||

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 | |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: For raw material, if its volume is greatly changed afterdrying, then its filling coefficient may be increased or decreased accordingly.A speed-adjusting motor of 0-6rpm might be chosen to use with the revolvingvacuum drying equipment, according to the user’s requirements. The followingaspects should be pointed out when ordering.

1. The above mentioned parameters are calculated based on material density of

2. If a certificate for pressure vessel is required, please request this

3. If a glass lining for interior surface is required, please request this.

If the raw material is explosive, or flammable, the calculation should be madeaccording to trial results.

Notice in Order

1. The revolving vacuum drying equipment has two methods: hot water and heatconduction oil.

2. When ordering, please indicate the temperature of the raw material to beused or the operation temperature of the dryer, in order to choose a suitableheat source for you.

3. When working with dry, viscous raw material, our factory will design aspecial stirring device in the chamber to accommodate this.

4. The auxiliary parts of the vacuum drying equipment can be supplied andinstalled by our factory. Please indicate them when ordering.

5. If you have any special requirements, our factory can also design,manufacture and install according to request.