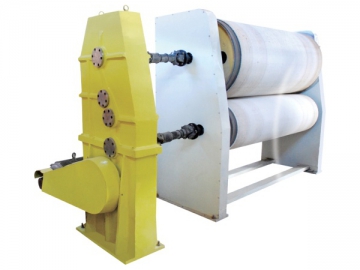

Corrugated Cardboard Double Facer

CorrugatedCardboard Double Facer

The corrugated cardboard double facer is made ofhigh intensity channel steel, which ensures firm structure, beautifulappearance and stable performance under high-speed running. It adopts thesingle-plate cross-linking and multi-group temperature control. Thepressurizing style of the machine uses intensive pressure roller or touch platefor option.

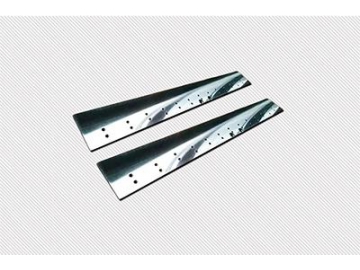

The hot plates of the corrugated cardboard double facer are professionallyfabricated conforming to the national safety standard, and go through theprecision grinding and hard chrome plating surface treatment. The inner S-shapeair flow structure improves the utilization ratio of steam, and the multiplesteel bars welded keep the hot plate not likely to deform. In addition, thehot plates of the corrugated cardboard double facer adopt separate temperaturecontrol or optional digital temperature display. What’s more, the inlet andoutlet of the steam piping are S-shaped, keeping the temperature of hot platessteady and balance. By the way, the quantity of hot plate can be set accordingto the speed and layer amount of the corrugated cardboard production line.

The cooling and heating parts of the corrugated cardboard double faceradopt intensive pressure roller to keep firm cardboard laminating and smoothshaping. The heavy roller of heating part uses entirely hydrauliclifting for steady, safe and reliable operation. Additionally, the bindingpart of the corrugated cardboard double facer adopts steam heating, and thepressurizing part utilizes completely hydraulic lifting or separate pressingaccording to the layer of production line, so as to provide suitable pressurefor cardboard binding and forming.

The upper cotton belt of the corrugated cardboard double facer is equipped withone set of automatic and manual correction device as well as one set ofpneumatic and manual strain device respectively. The lower cotton belt of thedouble facer is equipped with strain and automatic left-right adjustmentsystem. In addition, the upper conveyer belt adopts pneumatic straining,manual or automatic deflection-correction, and the lower conveyer belt adoptsmanual deflection-correction. What’s more, the upperconveyer belt can be provided with auto-cleaning system.

The driving part of the corrugated cardboard double facer adopts wear-resistantnetted rubber, reducing the possibility of belt skidding and improving thestability of operation. This machine also adopts independent reducer casingdriving and sealed oil bath gear transmission, making little noise. Inaddition, the double facer uses the independent drive box with dividedmechanism, adopting universal joint transmission to ensure smooth operation.

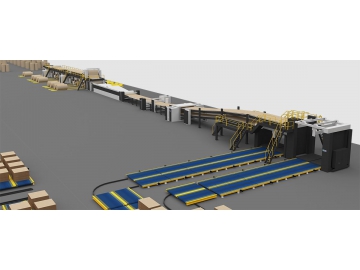

Technical Parameters of the CorrugatedCardboard Double Facer

Design speed: 120/180/220m/min

Working width: 1400mm-2500mm

Pressure roller:Φ70mm

Carrying roller:Φ70mm

Long belt front driven roller: Φ320mm

Long belt back driven roller: Φ215mm

Long and short belt deflection-correctedroller: Φ100mm

Front and back carrier roller: Φ100mm

Manual tension roller: Φ100mm

Hydraulic tension roller: Φ100mm

IndependentlyDriven Main Transmission Unit (Optional)

The corrugated cardboard double facer can be equipped with the independentlydriven main transmission unit for option. The drive gearbox applies skew geartransmission and the gear is made of high quality alloy steel, whose surface istreated with heating and tooth surface grinding, with low noise and largetorque. In addition, the independent drive box adopts direct two-shafttransmission and big drive gear to ensure the stability and reliability of the corrugated cardboarddouble facer during its high-speed running. What’s more, themain transmission part adopts variable-frequency motor with large adjustablerange and stable running. By the way, the bearing utilizes pump oil lubricatingand auto-splash lubricating is adopted for the gear inside the box.

Dinghao Machinery is aprofessional corrugated cardboard double facer manufacturer and supplier in