ForgedPart Manufacturer,Forging Parts, Steel Forging

Products

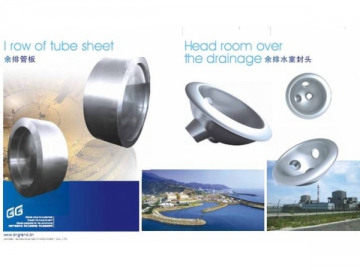

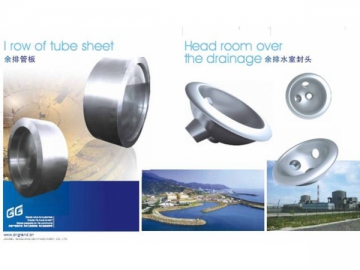

1.Nuclear Power Forged Parts

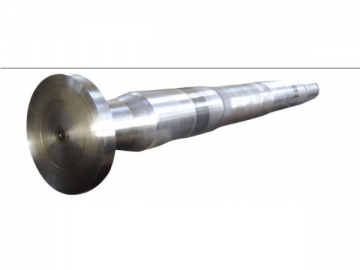

2.Wind Power Turbine Shaft

(1.5MW wind powerturbine shaft)

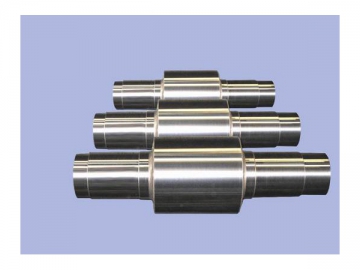

3.Ship Forged Part

(Propeller shaft)

4.Automotive Forging Module

5.Large Parts for Metallurgy

(Metallurgysupporting roll)

6. Other Forging Parts

(Roll for other industries)

ProductionCapacity

Our company specializes in the design and manufacture of large forgedparts. With a 7000 Ton hydraulic machine, we are able to process 70 Ton largeforged parts. With an annual output of 80,000 Tons, we forge for domestic andforeign shipyards 10,000-300,000 Tons of accessories for ocean-going ships,including stern shaft, intermediate shaft and bent rudder stock series. Forwind power companies we provide spindle for wind turbine for different power,ranging from 0.85 MW to 5 MW. For companies in metallurgical industry we offervarious types of large work rolls and support rolls. For companies inpetrochemical industry or pressure vessels manufacturers, we offer severaltypes of shells and hydro-cylinders. We also provide motor and steam turbineplants with rotor shaft and impeller.

(4000 Ton open-die forginghydraulic machine)

(7000 Ton open-die forginghydraulic machine)

The open-dieforging hydraulic machine has been designed with four columns, three cylindersand pull-down structure, which ensures excellent performance, fast forgingspeed, high degree of automation, strong anti-eccentric load capability andother properties.

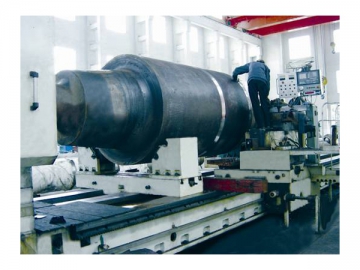

The large CNC lathe featuresmaximum working length of 24 m, maximum working diameter of 2.5 m with amaximum weight of 80 Ton.

(The machining of intermediateshaft for large grinding machine)

The largeNC roll grinder features working weight of 60 Ton, working length of 12.5m whitdiameter of 2.2m

The 3 m x 10 m gantrymilling machine features working length of 10 m and a working width of 3 m.

The deep hole boring machinefeatures a maximum boring depth of 9 m and a maximum diameter of 1 m.

The TK6926 CNC floor type boring machine features a maximum boring depth of 6 mand a maximum length of 14 m.

The CNC vertical lathefeatures working height of 2.5 m, working diameter of 3.15 m and 2 m loadbearing.

The large vertical sawing machine has a working diameter of 2 m.

We provide heat treatment equipment, such as large heating furnace, vacuumtempering machine, 22000 x 5000 x 4500 mm quenching pool, etc. These processingmachines work in perfect conditions; they can meet costumers’ requirements offorged parts for civil nuclear facilities.

The 100T double-pole series electroslag refining furnace isunder construction, it will be ready to start production in 2012 providing highquality steel ingot for the manufacture of nuclear power forged parts. At thesame time, the 17000 Ton hydraulic machine is also under construction. Oncecompletion, it can produce super large nuclear forged parts, ship forged parts,metallurgy big parts and other pieces.

Quality Control

Jiangsu Guoguang Group makes strong emphasis on theconstruction of quality assurance and inspection system, which applies frompersonnel appointed to follow the process of quality control and inspection tothe final product. Currently, we have 25 sets of testing equipment, likephysical and chemical flaw detector, which also guarantees high quality offorge parts.

In addition, we have detailed inspection records for each production process,such as raw materials analysis, heating, forging, heat treatment, performancetesting, flaw detection andmay others. Due to these tracking records, we can not only control forgedparts quality but also improve production technology through data analysis.

Certificates and Patents

Jiangsu Guoguang Group has passed the ISO9001: 2000 qualitysystem certification and is also certified by LR, GL, CCS, ABS, DNV and otherinstitutions.

Since our establishment, we have been committed to innovation, research anddevelopment. We have a series patents authorized by State Intellectual PropertyOffice, such as high-pressure air furnace with anti-infrared radiation system,steel ingot heat preservation cylinder, electric oil heating calender roll, calender roll with built-intemperature measuring equipment and metal band sawing machine. The pendingpatents include split anvil block, forging mandrel, forging mandrel with abrush, forging spherical anvil block, split spherical anvil block, platformtruck roller for forging furnace and platform truck guide roller.

Development History

In 2005, Jiangsu Guoguang Heavy Machinery Co., Ltd is established.

In 2007, we develop 1.5MW-3.0MW series in accordance with national developmentneeds of wind power industry and achieve capacity to produce 1200 sets of windpower turbine shaft per year, becoming one of the most important wind powerturbine shaft manufacturers in China. For ship forged parts, weprocess a whole set of shaft and rudder forgings for vessels with a maximumweight of 176,000 Ton.

Since 2009, we have been devoted to the research and development of AP1000nuclear power forged parts. Recently, we have developed production equipmentand technology and succeeded in manufacturing test of water chamber head, tubesheet and the bottom head of voltage regulator.

Since 2010, 7000 Ton hydraulic machine is operating.In July, large nuclear power forged parts are successfully developed.

In 2011, 17000 Ton hydraulic machine startsits assembly. Once completion, it will produce large nuclear forged parts, shipforged parts, large parts for metallurgy and more.

Strength

Currently, we have established a long-term strategic partnership with severallarge companies including GuodianUnited Power Technology Co., Ltd., Dongfang.Turbine Co., Ltd., Jiangsu Xinde Petroleum Machinery Co.,Ltd. We look forward to work with you.

Jiangsu Guoguang Group is close to Shanghai-Nanjing Expressway, Expresswayalong the Yangtze River,010 National Highway, Shanghai-Nanjing Railway and Xinyi-Changxing Railway. This essential location, 5Km from Yangtze Riverand 250 Km from Shanghai Port, plays an important role tosave costs in production and final shipping.