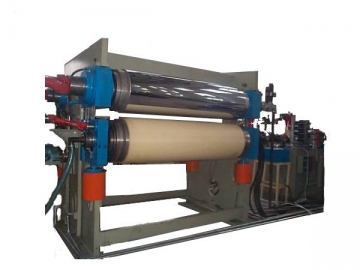

SoftCalendering Machine

The fixed crown soft calendering machine (single nipand double nip) is suitable for calendering paperwith a deckle less than 1880 mm. The internal multi-zones crown controllableroll soft calendering machine (single nip and doublenip) is suitable for calendering paper with a decklemore than 1880 mm.

The soft calendering machine can not only produce good effects, butgreatly improves uniformity of sheet density and ensures less dots orimperfections and better printing on paper. Consequently, the soft calendering machine is replacing the hard calendering machine in many paper mills.

Working Principle

Calendering is a repeating process,passing paper between a smooth roll surface and a coarse web surface afterpaper comes out of the drying section. The working principle of a soft calendering machine can be equivalent to ironing, makingsmooth passes with heat and pressure. The common calendering machine and super calenderingmachine both achieve greateffects through the repeated pressure of multiple rolls. The soft calenderingmachine accomplishes the calendering process risingthe surface temperature of rolls and width of nip. After process is finished,the smoothness of paper can be increased up to 30-40%while the paper thickness only reduces 10%.

Advantages

When pressurizing, elasticdeformation of soft roll leads to surface contact between hard roll and softroll. The surface contact width of soft calenderingmachine is 10-25 mm, which is 15 times more than a hard calenderingmachine. In addition, the unitary linear pressure of the soft calendering machine is generally 20-40 N/mm, even if thelinear pressure is higher; it’s just 1/2-1/4 of the hard calenderingmachine. The sheet stays longer in the nip while the heat energy passes tosheet and makes it fiber plastify. The softeningfiber is easier to be calendered, thus increasingsmoothness.

The rebound resilience ofsurface material makes the soft roll face suit any bad flatness of sheet andbase weight change, so the soft calendering machinecan achieve better softness than a common calenderingmachine, increasing color, spots can be eliminated and printability can begreatly improved.

Another advantage of the soft calendering machine is,when paper is being pressed black and basic elimination of color spots, sheetcan be in motion to hold higher moisture. The temperature, nip pressure, widthand number of soft calendering machine all haveeffect on smoothness or shiny results.

Main parameters

| Item | Index |

| Paper Web | 1880-10000 mm |

| Speed | 50-1000 M/Min |

| Linear pressure | 50-300 KN/M |

| Temperature | 18 0 °C Max |

Applications of the CCR Soft Calendering Machine

1. Standard newsprint (DIP)

2. Improved newsprint

3. SC-B rotogravure

4. LWC (Light weight coatingpaper) offset

5. Coated or uncoated woodfree paper

6. Coated or uncoated board

7. Print and writing paper

We are a China soft calendering machine manufacturerand supplier. We offer various types of products such as super soft calendering machine, hard calenderingmachine, multi-functional up and down double-sided press calenderingmachine and two roll fabric calendering machine.