Spiral Welded Steel Pipe

Spiral Welded Steel Pipe

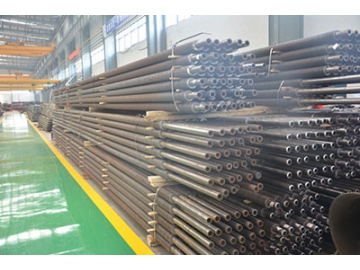

Spiral welded steel pipe is produced through rolling the low carbon structural steel or low alloy structural strip steel to tube billet according to certain spiral angle and welding the billet at the tube seam. The production for the product is flexible. The product with large diameter can be made by using narrow steel raw material. Meanwhile, the steel raw materials with same width can be produced to the spiral welded steel tube with different diameters.

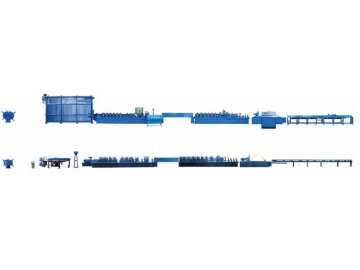

We have the capability of producing large quantity of spiral submerged arc welded steel pipes stably and continuously. With seven sets of spiral welded steel tube production lines available, we can produce the product with the diameter and wall thickness of 219 to 3000mm and 4 to 25mm respectively. The adopted materials for the product are Q235, Q345 and pipeline steel with the steel grade of A to X80. Our product can meet the needs of different occasions.

Application Range

1. The spiral welded steel pipe can transport fluids involving in water supply, water drainage, chemical liquid transportation, petroleum delivery, etc.

2. The product can also be used for conveying gas such as coal gas, steam, liquefied petroleum gas and more.

3. The spiral welded steel tube can also be applied as piling tube, clutch steel tube and structural tube in dock, road, construction and so on.

Differences of the Spiral Welded Product and Longitudinal Welded Product

1. The coil rolling direction of the spiral welded steel pipe is not vertical to the axis of the product. The angle between the two directions depends on the spiral angle of the spiral welded product. However, the steel plate rolling direction of longitudinal welded product is vertical to the axis of the product. So, in the aspect of anti cracking capability, the spiral welded product is superior to the longitudinal welded product.

2. For the spiral welded product, the spiral angle of the welding seam is often 50 to 75°. So, the composite stress at the spiral welding seam is 60% to 85% of the primary stress of longitudinal welded product. Under the same working pressure, the wall thickness of the spiral welded product can be smaller than that of longitudinal welded product with the same diameter.

Related Names

SSAW Steel Pipe | Spiral Welded Tube