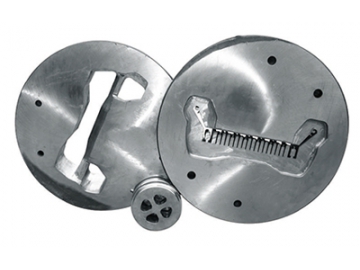

Aluminum Extrusion Press

Description

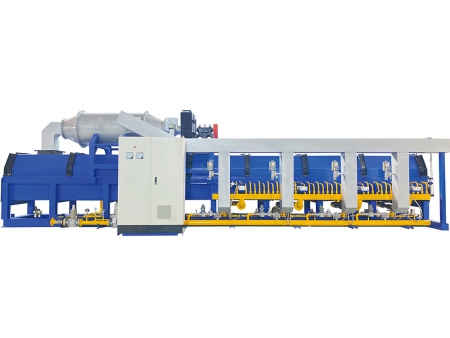

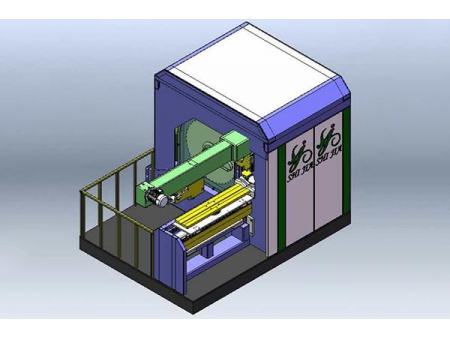

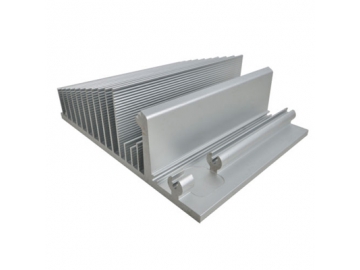

As one of the industry’s leaders in extrusion press, we provide aluminum extrusion presses with different tonnage ratings to accommodate both small and large extruded aluminum shapes. Our aluminum extrusion equipment can be used for manufacturing precise extrusions with the industry’s tightest tolerances.

In the aluminum industry, there are direct and indirect extrusion processes available for different applications. Direct aluminum extrusion press is the most commonly used based on the working principle of hydraulic press.

Technical parameters

| Model | Working Pressure Mpa | Plunger Diameter mm | Side Cylinder Size mm | Size of Aluminum Billet mm | Extruder Height mm | Outlet Size (mm) | Total Power | Outside Diameter (mm) | Total Weight (T) |

| 500T (550UST) | 21 | ø 520 | ø 125×ø 70 | ø 80×380 | 850 | ø 110x110 | 72 | 5700×3100×2500 | 20 |

| 600T (660UST) | 21 | ø 580 | ø 160×ø 120 | ø 90×480 | 850 | ø 110x110 | 105 | 6000×3200×2600 | 24 |

| 700T (770UST) | 21 | ø 620 | ø 160×ø 120 | ø 100×520 | 1030 | ø 120x140 | 130 | 7900×2800×3500 | 38 |

| 800T (880UST) | 21 | ø 660 | ø 180×ø 140 | ø 110×530 | 1050 | ø 130×150 | 132 | 8500×3015×3560 | 42 |

| 1000T (1100UST) | 21 | ø 750 | ø 200×ø 150 | ø 120×600 | 1095 | ø 140×160 | 195 | 9660×3070×3900 | 53 |

| 1250T (1400UST) | 21 | ø 840 | ø 200×ø 150 | ø 140×650 | 1180 | ø 170×200 | 250 | 11920×3230×3900 | 65 |

| 1400T (1540UST) | 21 | ø 870 | ø 220×ø 150 | ø 150×680 | 1180 | ø 180×210 | 260 | 11920×3230×3900 | 70 |

| 1650T (1800UST) | 21 | ø 950 | ø 220×ø 150 | ø 178×800 | 1530 | ø 210×260 | 315 | 13400×3580×4900 | 90 |

| 2000T (2200UST) | 21 | ø 1050 | ø 250×ø 180 | ø 200×800 | 1680 | ø 240×300 | 350 | 1650×4000×5100 | 136 |

| 2500T (2750UST) | 21 | ø 1180 | ø 250×ø 180 | ø 228×1000 | 2030 | ø 280×350 | 550 | 17500×6000×6500 | 250 |

| 3000T (3300UST) | 28 | ø 1180 | ø 250×ø 180 | ø 254×1000 | 2030 | ø 338×480 | 780 | 17500×6000×6500 | 300 |

| 4350T (4785UST) | 28 | ø 1350 | ø 320×ø 220 | ø 280×1000 | 2280 | ø 450×500 | 960 | 19500×6900×7500 | 350 |

| 5500T (6000UST) | 28 | ø 1500 | ø 380×ø 250 | ø 400×1200 | 2350 | ø 490x620 | 1660 | 22000×8000×10000 | 650 |

| 8200T (9000UST) | 28 | ø 1780 | ø 480×ø 320 | ø 485×1750 | 2585 | ø 550×800 | 2500 | 28000×9800×11000 | 800 |

Features

- Dead cycle time is shortened, increasing production efficiency.

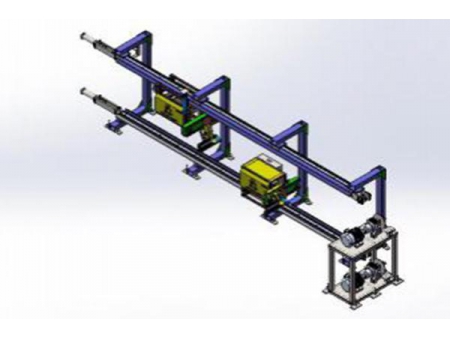

- Billet loader is controlled by the servo motor, ensuring billets are fed in a faster, more precise and more reliable manner.

- Extrusion press container is heated by heating pipes, providing quick heating with high heating efficiency.

- The elastic deformation is significantly reduced because of a specially designed structure.

- The length of tie rod and main cylinder is shortened, increasing the stability and precision of the extruder.

Related products

Send Message

Most Recent

More

Other Products

Videos