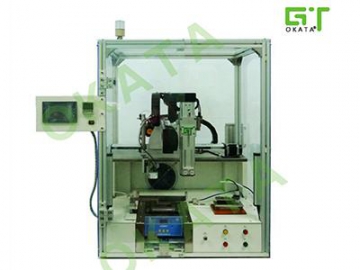

Auto Component Inserting Machine

The auto component inserting machine is designed to weld Through-Hole Mounting (THM) components, such as power supply product, household appliances control panel, electric toy, switch plate, connector pinboard, LED product, charger and so on. This auto component inserting machine is capable of realizing large batch production and it can be also used for the soldering test and dip soldering temperature resistance test of components.

- Intelligent PLC control, free set of all welding parameters.

- Three sets of high-performance motor systems. Interlocking control simulates manual welding operation.

- Capable of welding 30*30mm-350*300mm 600C 30*30mm-600*350mm PCB.

- Fast up to 10 seconds complete dip soldering (operable without professional technicians)

- 400-degree high temperature design meets the welding or soldering requirements of different materials, which effectively reduces solder input.

- Double temperature protection (overtemperature protection)

- Anti-collision protection and the indicator light flickers when under protection. Three sets of the motor systems all have time protection mechanisms to protect them from overheating damage.

- Pre-heating function added.

- Ductile cast iron heating unit can achieve 600-degree temperature without burning. (Long service life design)

- Lead-free solder furnace: highly temperature resistant, highly corrosion resistant, Switzerland 316L High nickel stainless steel.

- Dip soldering heating curve measuring system is optional, which can measure the temperature resistance of all components and test the soldering status of the sensitive detectors.

- Small capacity: 500C (75KG-100KG) 600C (120KG-140KG).

- Weldable for 2-45mm components or plane soldering.

- Auto power on and off without waiting.

- Omron intelligent panel control KETE SSR solid state heating control.

- Satisfying the soldering requirements of PCB, LED, transformer and other electric components. (with appropriate fixtures)

- Upgraded functions: text display operation system, permission operation and counting function.

When using a manual dip soldering pot, it takes a professional technician at least 5 seconds for one dip soldering stroke and after 8-hour continuous work he can dip solder 5760 times. The smaller the circuit board, the lower the production quantity; the bigger the circuit board, the worse the soldering quality and quality consistency. The technicians need to have skillful experience and to be paid high wages, which increases the labor cost. Furthermore, the long-time usage of manual dip soldering pot is harmful to human health.