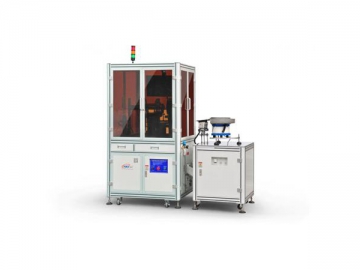

Visual Inspection Machine for Automotive Fasteners Testing

Types: Glass plate optical sorting machine

Suited for: Auto nuts, auto screws, tire valves, oil seals and other auto parts

Inspecting products

Technology parameters:

| Model | RK-1500 |

| Head Outer Diameter (mm) | 1-25 |

| Head Thickness (mm) | 1-15 |

| Total Height (mm) | 1-25 |

| Inspection Accuracy | ±0.01mm |

| Air Pressure (Kg/cm²) | 5 |

| Host Computer | Industrial PC |

| Digital Camera | Industrial CCD |

| Net Weight (KGS) | 650 |

| Dimension (mm) | 1350*1100*1800(LWH) |

Features

- Due to the high transparency of glass, this machine can inspect all the products which can be placed stably on the glass platform.

- 2 to 6 additional CCD cameras can be installed according to the inspection parameters on your checklist.

- The inspection and sorting speed depends on the feeding system, up to 500-1200 pieces per minute.

- An automatic counting and packing machine and automatic feeder can be added according to your requirements.

- Parts can be quickly and easily changed.

- 30min inspection line changing time

For inspecting products of similar size and type, this machine does not require the changing of accessories. Simply load the parameters using the software. For inspecting products of different types, the changing time for accessories is no more than 30 minutes depending on the skill level of the operator.

- Miss-sorting prevention

Both NG and OK products are blanked by compressed air. Its design can effectively prevent NG products from being carried to the OK outlet even in the case of malfunction.

- Easy-to-use software

The software enables the easy setting of various inspection parameters for different products. It allows you to create different accounts with levels of privilege with password protection to prevent operators from tampering with parameters.

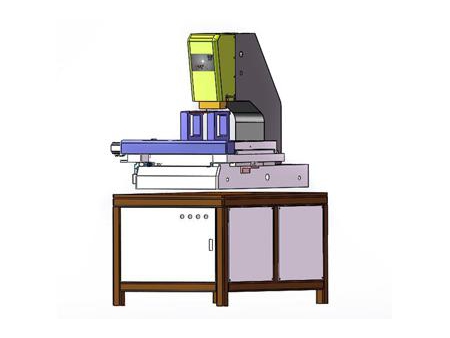

Optional accessories

Vibration bowl

Vibration bowl Feeding elevator

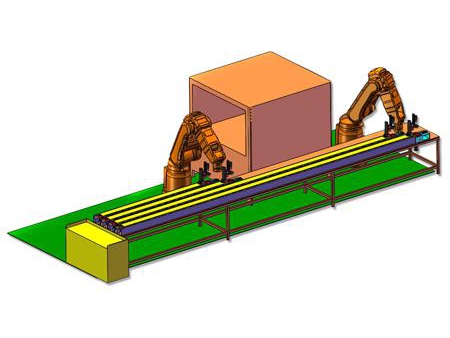

Feeding elevator Automated conveyor system

Automated conveyor system

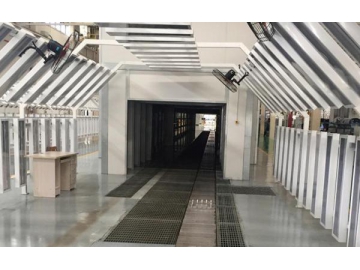

Related products

Send Message

Most Recent

More

Other Products

Videos